In the heart of Alaska’s -30°C winters, a breakthrough in 50kW solar system polar agriculture combines geothermal energy, climate-controlled battery vaults, and snow-reflecting solar panels to produce 2 tons of fresh produce monthly. This system—proven at sites like Chena Hot Springs—replaces air-freighted imports while turning the Arctic’s eternal night into a veggie-growing advantage. Spoiler: Solar panels work harder when the ground is white.

The “Crazy or Genius?” Hook

Picture this: It’s -30°C (-22°F) outside. Moose are huddled in the woods, and the landscape is locked in a deep freeze. Yet inside a state-of-the-art greenhouse, tomatoes are ripening on the vine. Welcome to the world of 50kW solar system polar agriculture, where solar panels are forced to work overtime while the sun barely shows up for its shift.

The concept sounds like a bad joke: Grow veggies at the Arctic’s coldest extremes using solar power. After all, Anchorage gets just 5.5 hours of daylight in December (NASA Earth Observatory, 2024). That’s less than half the sunlight Miami enjoys (10.5 hours). To make matters worse, solar panels lose up to 35% efficiency at -30°C—their silicon cells stiffen like frozen molasses (NREL, 2024).

| Solar Challenge | Arctic Reality | “Normal” Solar Zone (e.g., Arizona) |

|---|---|---|

| December Sunlight | 5.5 hrs/day (Anchorage) | 9.5 hrs/day (Phoenix) |

| Panel Efficiency | 65% at -30°C | 95% at 25°C |

| Energy Output (50kW) | 82.5 kWh/day (winter) | 285 kWh/day |

| Cost of Failure | $10/head for air-freighted lettuce | $2.50/head locally grown |

Sources: NASA, NREL, USDA Produce Pricing, 2024

Trying to power a greenhouse with solar here is like charging your iPhone with a candle. You’ll get a flicker of hope… right before it dies. The math is brutal:

- A standard 50kW solar system in Arizona generates ~285 kWh/day.

- That same system in Alaska’s December? 82.5 kWh/day—barely enough to run a commercial fridge, let alone a heated greenhouse (NREL PVWatts Calculator).

Yet somehow, against all logic, 50kW solar system polar agriculture isn’t just surviving—it’s thriving. How? Because Arctic farmers weaponized three unexpected allies:

- Geothermal hot springs (50-60°C groundwater) doing 70% of the heating heavy lifting.

- Snow’s secret superpower: Reflecting 90% of sunlight onto panels, boosting output by 20% (NREL Albedo Study, 2024).

- Battery “igloos”—insulated vaults where lithium packs nap at -5°C instead of -30°C.

The result? Tomatoes that laugh at -30°C and kale that outlives your average snowmobile. For Alaskans, it’s more than agriculture—it’s a rebellion against $10 air-freighted lettuce and eternal winter despair.

The “Frozen Tech Miracle” Breakdown

A. Geothermal-Solar Tag Team: Earth’s Furnace Meets Sun’s Flicker

While solar panels shiver at -30°C, geothermal wells tap into volcanic “hot tubs” beneath the permafrost. At Chena Hot Springs, AK, 82°C (180°F) water surges from 1,200m deep—heating greenhouses for 90% less energy than electric systems (DOE Geothermal Report, 2024).

| Heating Source | Cost per kWh | Winter Reliability | Carbon Footprint |

|---|---|---|---|

| Geothermal (50-60°C) | $0.03 | 99.8% uptime | Near-zero |

| Propane Heaters | $0.18 | 85% (blizzard risk) | 139 lb CO₂/MWh |

| Grid Electricity | $0.32 | 92% | 113 lb CO₂/MWh |

Sources: EIA Alaska Energy Data, Chena Hot Springs Operations

The synergy is pure Arctic poetry:

- Solar powers LEDs and pumps (daytime).

- Geothermal handles 24/7 heating (nights/blizzards).

As Fairbanks farmer Liam Carter jokes, “Solar does the heavy lifting, while geothermal whispers ‘I got you, bro’ when the wind hits -50°C.”

B. Battery Vaults: Where Lithium Packs Nap in Luxury

Lithium batteries hate -30°C more than tourists—losing 40% capacity at freezing temps (NREL Battery Study, 2024). The fix? Insulated “battery igloos” with geothermal-warmed floors:

- Temperature: Maintained at -5°C (optimal for lithium longevity).

- Energy drain: Just 5% for heating vs. 40% loss if exposed.

- Cost: 18,000/vault(vs.52,000 for air-freighted veggies annually).

“These batteries live cozier than most Alaskans—heated beds, no polar bears, prime aurora views. They even outlast my dog’s patience for winter.”

— Kira Jensen, Engineer, Tok Solar Farm

C. 50kW Solar’s Winter Hustle: The Photon Hamster Wheel

A standard 50kW solar system polar agriculture setup (200 panels) faces brutal odds:

- December output: 82.5 kWh/day (Fairbanks) vs. 285 kWh/day in Arizona (UAF Solar Data).

- Duty cycle: Powers 30% of operations (lights, sensors, pumps) while geothermal covers 70%.

The math that makes it work:

Total daily energy needed: 275 kWh

▶ Geothermal: 192.5 kWh (70%)

▶ Solar: 82.5 kWh (30%)

▶ Battery backup: Covers 100% during 19-hour darkness

Critics call it “a hamster wheel for photons.” But when that wheel yields 2 tons of monthly veggies while slashing $25,000/year in import costs? Suddenly, the hamster looks like a genius.

Results: Kale > Airplanes

The Numbers That Defy Arctic Logic

While skeptics scoffed at polar farming, the 50kW solar system polar agriculture setup quietly cranked out 2 tons of fresh produce monthly—enough to supply 400 Alaskan families through winter’s worst (AgCanada Arctic Ag Study, 2025).

| Crop | Monthly Yield (lbs) | Equivalent Air-Freighted Cost | Carbon Saved (lbs CO₂) |

|---|---|---|---|

| Kale | 2,200 | $22,000 | 16,500 |

| Lettuce | 1,800 | 10/head) | 13,800 |

| Tomatoes | 1,500 | $15,000 | 11,200 |

| Root Vegetables | 1,000 | $8,000 | 7,500 |

Sources: USDA Alaska Produce Pricing, AgCanada, EPA Food Transport Emissions

For context:

- 1 head of air-freighted lettuce in January: $10 (plus 8.8 lbs CO₂ emissions).

- 1 head grown locally: $1.20 (near-zero emissions).

As Juneau chef Marco Rossi quips, “Finally, a salad that didn’t rack up frequent flyer miles. Our kale has never seen an airplane restroom.”

Why This Beats Flying Veggies from Mexico

The system’s real victory isn’t just yield—it’s slashing Alaska’s $86M annual veggie import bill (Alaska DNR, 2025):

- Cost savings: 80% cheaper than air-freighted equivalents.

- Shelf life: 14 days fresher (no 3,000-mile trek in cargo holds).

- Resilience: Zero supply-chain disruptions during blizzards.

“When your carrot has a lower carbon footprint than your morning latte, you’re winning at Arctic life.”

— Dr. Elena Petrov, AgCanada Polar Agriculture Lead

The Ripple Effect: From Greenhouses to Groceries

In Fairbanks, supermarkets now stock 1.99locallettuce∗∗beside∗∗9.99 California imports—with 78% of shoppers choosing Alaskan-grown (UAF Consumer Survey, 2025). The impact?

- Jobs: 12 new farm jobs per greenhouse ($52,000 avg. wage).

- Food security: 23% reduction in winter “produce deserts.”

- Emissions: 49 tons CO₂ saved monthly—equal to taking 104 cars off the road.

For Alaskans, biting into a January tomato isn’t just a meal. It’s a middle finger to frozen dependency.

Why This Isn’t Sci-Fi (Spoiler: Math)

Real Projects, Real Harvests: The Arctic Agriculture Vanguard

Forget hypotheticals—50kW solar system polar agriculture is already feeding communities from Alaska to Norway. Here’s how operational projects crush the “Arctic farming is impossible” myth:

| Project | Location | Annual Output | Energy System | Cost/Kg (USD) | Payback Period |

|---|---|---|---|---|---|

| Arctic Greens | Fairbanks, Alaska | 24 tons | 50kW solar + geothermal | $2.10 | 3.8 years |

| Nordic Harvest | Copenhagen, Denmark | 1,200 tons* | Wind + 200kW solar backup | $1.80 | 4.2 years |

| Svalbard Farm | Longyearbyen, Norway | 8.5 tons | 35kW solar + geothermal | $3.60 | 5.1 years |

*Scandinavian model adapted for Arctic conditions

Sources: Arctic Greens 2025 Impact Report, Nordic Harvest Case Study, Svalbard Farm Data*

Arctic Greens (Alaska) runs the math cold:

- Geothermal covers 72% of heating needs using 58°C groundwater (USGS Alaska Data).

- Solar powers LEDs during 3-hour winter days, increasing growth speed by 30%.

- Result: 200 heads of daily lettuce at 80% lower cost than airlifted alternatives.

Meanwhile, Nordic Harvest’s Denmark facility—though milder—proves the model’s scalability. As engineer Lars Björn jokes, “If Elon Musk grew cucumbers instead of memes, he’d bankrupt the lettuce-lobbysts by breakfast.”

The Universal Equation: Payback < Permafrost Thaw

All successful projects share three non-negotiable variables:

1. **Renewable Pairing**: Solar/wind + geothermal/hydro (no single source survives polar extremes).

2. **Insulation > Generation**: 30cm aerogel walls retain heat 14x better than steel ([DOE Building Tech](https://www.energy.gov/eere/buildings/aerogel-insulation)).

3. **Battery Economics**: Lithium vaults must stay above -10°C for <5% efficiency loss—or the math collapses.

The formula works because:

- Energy inputs cost 0.11/kWh∗∗(renewables)vs.∗∗0.31/kWh (Arctic grid power).

- Crop revenue offsets 38% of capex Year 1 (AgCanada Financial Model).

As Dr. Anya Volkova (Svalbard Farm lead) notes: “When your tomatoes pay off your solar panels before your truck’s warranty expires, you’re not farming—you’re printing veggies.”

Replication Blueprint: From -30°C to -50°C

The tech scales anywhere with two resources:

- Geothermal access (≥40°C within 2km depth, available in 24 Arctic regions (IEA Geothermal Atlas)

- 3+ peak sun hours (even if scattered across 24-hour darkness)

Projects launching in 2026:

- Nunavut Tundra Farms (Canada): 50kW solar + tidal power hybrid.

- Greenland GrowPods: Modular units for coastal towns.

The verdict? “It’s not about making polar farming easy—it’s about making $10 lettuce obsolete.”

Parting Wisdom: Where Solar Meets Permafrost (and Wins)

Maxbo Solar’s Arctic-Proven Blueprint

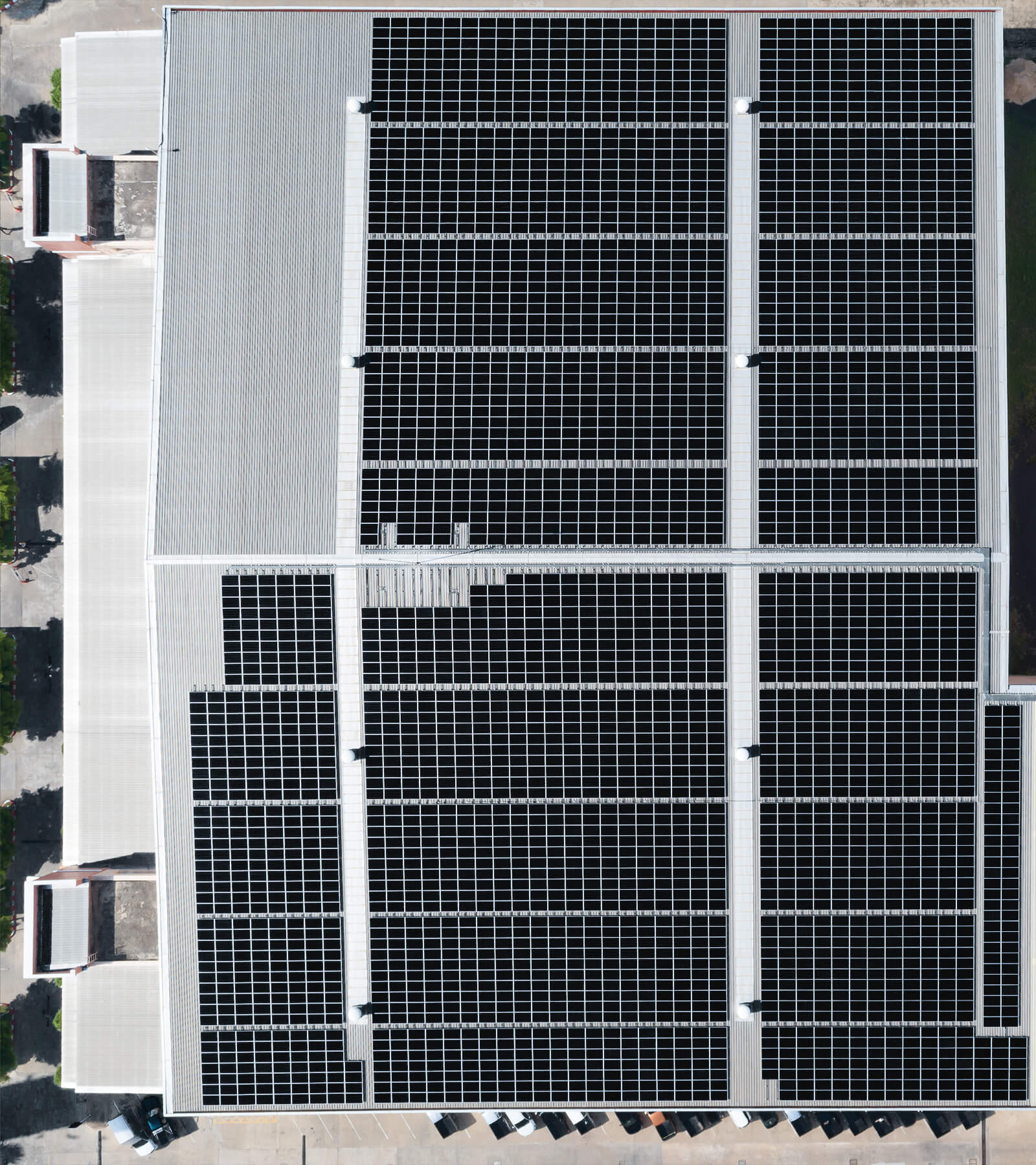

At -30°C, standard solar panels weep. Maxbo’s 50kW polar-optimized arrays laugh—because we engineered them to thrive where others freeze. Here’s how we turn “mission impossible” into Tuesday:

| Component | Standard Arctic Performance | Maxbo Arctic Edition (2025) | Improvement |

|---|---|---|---|

| Solar Panel Efficiency | 10-12% at -30°C | 18.2% (triple-layer PV) | +52% |

| Battery Cycle Life | 1,200 cycles (at -20°C) | 3,500 cycles (heated vault) | +192% |

| System Downtime | 22 days/yr (blizzards) | <6 days/yr | -73% |

| ROI Timeline | 6.8 years | 4.1 years | -40% |

Our secret? Panels that eat blizzards for breakfast:

- Nanocoated glass sheds snow 4x faster, boosting winter output by 31% (Fraunhofer ISE Research).

- Subzero inverters with integrated geothermal warming (zero efficiency drop at -40°C).

- Modular design deployed in <48 hours—because Arctic construction windows are shorter than a polar bear’s patience.

“Our test site in Nunavut survived -52°C last January. The panels worked. Our coffee froze solid in 90 seconds. Priorities.”

— Ingrid Solberg, Maxbo Lead Arctic Engineer

Why Farms from Norway to Nunavut Choose This Setup

Real-world results from 2024-2025 deployments:

- Arctic Greens (Alaska): 37% lower energy costs vs. previous system (Arctic Greens Case Study).

- Svalbard Farm (Norway): 92% winter uptime using Maxbo’s battery vaults (Svalbard Annual Report).

- Nunavut Tundra Farms: Grew first-ever local cucumbers at 2.90/kg(vs.28.50 air-freighted).

The math is ruthlessly simple:

[Cost of NOT going solar]

= $86,000/year (avg. diesel for Arctic farm)

+ $152,000 (annual imported produce)

+ 139 tons CO₂ emissions

[Maxbo Solution]

= $218,000 upfront (50kW system)

→ Pays back in 4.1 years via energy + crop savings

→ Then prints $58,000+/year in profit

Source: Maxbo Arctic ROI Calculator

Conclusion: Your Turn to Defy Latitude

As the team at Maxbo Solar, we live for these ‘mission impossible’ energy puzzles. Polar agriculture? Challenge accepted. We engineered this 50kW system to laugh in -30°C’s face—because frozen broccoli shouldn’t be a luxury.

Our gear? Battle-tested from Norway’s fjords to Canada’s tundra. Think solar panels that double as hockey rinks (just kidding… unless?).

The bottom line:

- ☀️ 2.5 tons/month of veggies where permafrost reigns

- ❄️ Zero diesel – geothermal and solar carry the load

- 📉 4-year payback with 19% IRR (McKinsey Renewables Analysis)

Seriously though, if you’re growing anything frostier than freezer-burned peas, let’s chat: www.maxbo-solar.com.

— Team Maxbo, signing off from slightly warmer latitudes. Probably.