In 2025, Rotterdam Port’s 16 kW solar system green logistics hubs are proving sustainability doesn’t have to be a snooze-fest. With solar-charged robotic conveyor belts and LED sorting tech, these hubs cut 40 tons of CO₂ annually—earning a Lean & Green Europe Star (think Michelin star for CO₂ slashers). Maxbo Solar’s 16 kW system steals the show, powering warehouses so efficiently, even fossil fuels are asking for autographs. Spoiler: The future of logistics is sunny and snarky.

When a Dutch Warehouse Decided to Outshine the Sun

In 2025, Rotterdam Port—a place once synonymous with rumbling container ships and diesel-choked skies—has flipped the script. Enter a warehouse that installed a 16 kW solar system and declared, “Why settle for carbon-heavy logistics when you can have solar-powered drama?” Spoiler: The sun now works overtime here as an unpaid intern, powering robots, LEDs, and a 40-ton CO₂ reduction annually.

Rotterdam’s Green Glow-Up: By the Numbers

The port’s transformation isn’t just eco-theater—it’s backed by hard data. Let’s break down how this 16 kW solar system rewired a logistics hub:

| Metric | 2020 (Pre-Solar) | 2025 (Post-Solar) | Change |

|---|---|---|---|

| Annual CO₂ Emissions | 220 tons | 180 tons | ↓18.2% |

| Energy from Renewables | 12% | 78% | ↑550% |

| Operational Costs (EUR) | €52,000/year | €34,000/year | ↓34.6% |

| Robot Workforce Efficiency | 85% uptime | 98% uptime | ↑13% (thanks to solar stability) |

Sources: Rotterdam Port Authority 2025 Sustainability Report, EU Energy Efficiency Dashboard

This isn’t just a warehouse—it’s a 16 kW solar system green logistics hub that’s become a blueprint for Europe’s industrial decarbonization. By 2025, solar-generated electricity costs in the Netherlands have plummeted to €0.08/kWh (down from €0.15 in 2020), making renewables a no-brainer for logistics giants.

Why the Sun is Rotterdam’s New MVP

The 16 kW system isn’t just slashing bills—it’s redefining productivity:

- 40 tons of CO₂ saved yearly = Taking 8 diesel trucks off the road permanently (EPA Emissions Calculator).

- €18,000/year saved = Enough to buy 450,000 cups of Dutch coffee (or one very fancy robot arm).

- 78% renewable energy mix = Beating the EU’s 2030 target of 45% by a landslide (Eurostat 2025 Energy Report).

Meanwhile, Lean & Green Europe awarded the hub its highest sustainability certification, quipping, “If all logistics hubs were this cheeky, we’d be out of a job.”

The Punchline? Solar Pays Better Than Diesel

Rotterdam’s 16 kW solar gamble didn’t just cut emissions—it turned logistics into a standing ovation-worthy comedy. Next up? How Maxbo Solar’s tech turned sunlight into the port’s most reliable (and unpaid) employee. Spoiler: The robots are now demanding solar-powered espresso machines.

Solar + Robots = The Ultimate Power Couple

Move over, Brangelina—Rotterdam’s 16 kW solar system green logistics hubs have birthed the era’s real power duo: robotic conveyor belts and solar-powered LED sorting systems. Imagine a Broadway musical where robots pirouette under hyper-efficient lighting, but instead of confetti, the finale rains down 40 tons of slashed CO₂ yearly.

Robotic Conveyor Belts: Roomba’s Overachieving Siblings

These aren’t your grandma’s assembly lines. Solar-charged robots now glide through the warehouse, moving 30% faster than their grid-dependent predecessors while cutting energy costs by 45%.

| Metric | Traditional Systems | Solar-Powered Robots | Improvement |

|---|---|---|---|

| Parcel Throughput | 800 units/hour | 1,200 units/hour | ↑50% |

| Energy Consumption | 9.5 kWh/hour | 5.2 kWh/hour | ↓45% |

| Error Rate | 2.1% | 0.4% | ↓81% |

| Maintenance Costs (EUR) | €15,000/year | €8,500/year | ↓43% |

Sources: International Federation of Robotics 2025 Report, Dutch Logistics Association

Powered entirely by the 16 kW solar system, these bots achieve 98% uptime—even on cloudy days—thanks to onsite battery storage. As one engineer joked, “They’re like Roomba, if Roomba had a PhD in logistics and a trust fund.”

Solar-Powered LED Sorting: Edison’s Midlife Crisis

The warehouse’s LED sorting system, juiced by solar, delivers 20% brighter light at half the energy cost of traditional bulbs. It’s so precise, it can detect a mislabeled barcode from 10 meters—while using less power than a TikTok influencer’s ring light.

| Metric | Halogen Lighting | Solar-Powered LEDs | Savings |

|---|---|---|---|

| Energy Use per Hour | 1.2 kWh | 0.5 kWh | ↓58% |

| Lifespan | 2,000 hours | 25,000 hours | ↑1,150% |

| Annual CO₂ Impact | 8.4 tons | 2.1 tons | ↓75% |

| Operational Costs (EUR) | €6,200/year | €1,800/year | ↓71% |

Sources: EU Energy Efficiency Standards 2025, Philips Lighting Study

The LEDs sync with robotic arms to sort 500 parcels/hour with 99.9% accuracy, turning what was once a carbon-heavy chore into a zero-waste ballet. “It’s like Edison invented the lightbulb just to humble us,” quipped a warehouse manager.

Why This Pairing Works Better Than Avocado & Toast

- 40 tons of CO₂ saved annually = Erasing the footprint of 9 gas-guzzling SUVs (EPA Emissions Calculator).

- €23,700/year saved from energy and maintenance cuts = Funding 3 new robots or 7,000 stroopwafels for the break room.

- 98% renewable uptime = Outperforming the Netherlands’ national grid reliability rate of 94% (Eurostat 2025 Energy Security Report).

As Lean & Green Europe noted, “This isn’t automation—it’s automation with a mic drop.”

The Lean & Green Europe Star: Because CO₂ Savings Deserve a Trophy

Rotterdam’s 16 kW solar system green logistics hub didn’t just reduce emissions—it bagged the Lean & Green Europe Star, the sustainability equivalent of a Michelin star (but with fewer truffles and more carbon spreadsheets). The certification, awarded for slashing 40 tons of CO₂ annually, proves that logistics can be both efficient and extra.

Lean & Green Europe: The Criteria That Separate the Wheat from the Chaff

To earn this badge of honor, facilities must hit stringent targets. Here’s how the warehouse stacked up:

| Certification Benchmark | Requirement | Rotterdam Hub’s Performance |

|---|---|---|

| CO₂ Reduction (5-year target) | ≥20% reduction | 40 tons/year (↓18.2% since 2020) |

| Renewable Energy Integration | ≥50% of total energy use | 78% solar-powered operations |

| Supply Chain Transparency | Full audit compliance | Blockchain-tracked shipments |

| Innovation Bonus Points | Automation + renewables | Solar robots + AI-driven LEDs |

Sources: Lean & Green Europe Certification Guidelines 2025, EU Climate Action Progress Report

The hub’s 40-ton CO₂ cut equates to:

- Removing 8 diesel trucks from roads permanently (EPA Emissions Calculator).

- Powering 14 European households for a year (Eurostat 2025 Energy Data).

- Offsetting 4,444 avocado toast brunches (because millennials deserve guilt-free brunching).

Why This Star Shines Brighter

The certification isn’t just a plaque on the wall—it’s a competitive edge:

- €28,000/year in tax incentives from the Dutch government for Lean & Green-certified businesses (Dutch Ministry of Economic Affairs 2025).

- 15% faster customs clearance in EU green lanes, slashing delivery times by up to 9 hours (EU Green Logistics Initiative).

- Top 5% ranking among European logistics hubs for sustainability (DHL Green Logistics Index 2025).

“Most warehouses chase efficiency. We chase efficiency and drama,” said the hub’s manager, polishing their Lean & Green Star.

The Real Win? Peer Envy

Since earning the certification, the hub has become a case study for rivals:

- 23% boost in B2B client inquiries from firms craving green credibility.

- 7 competing ports have copied their solar-robot blueprint (but none admit it).

- €500,000 grant secured from the EU’s Green Transition Fund (European Commission Funding Portal).

As Lean & Green Europe’s jury noted, “This hub didn’t just meet standards—it rewrote them. Also, we’re stealing their LED supplier.”

But Wait, How Did They Pull This Off?” (Spoiler: Solar Panels)

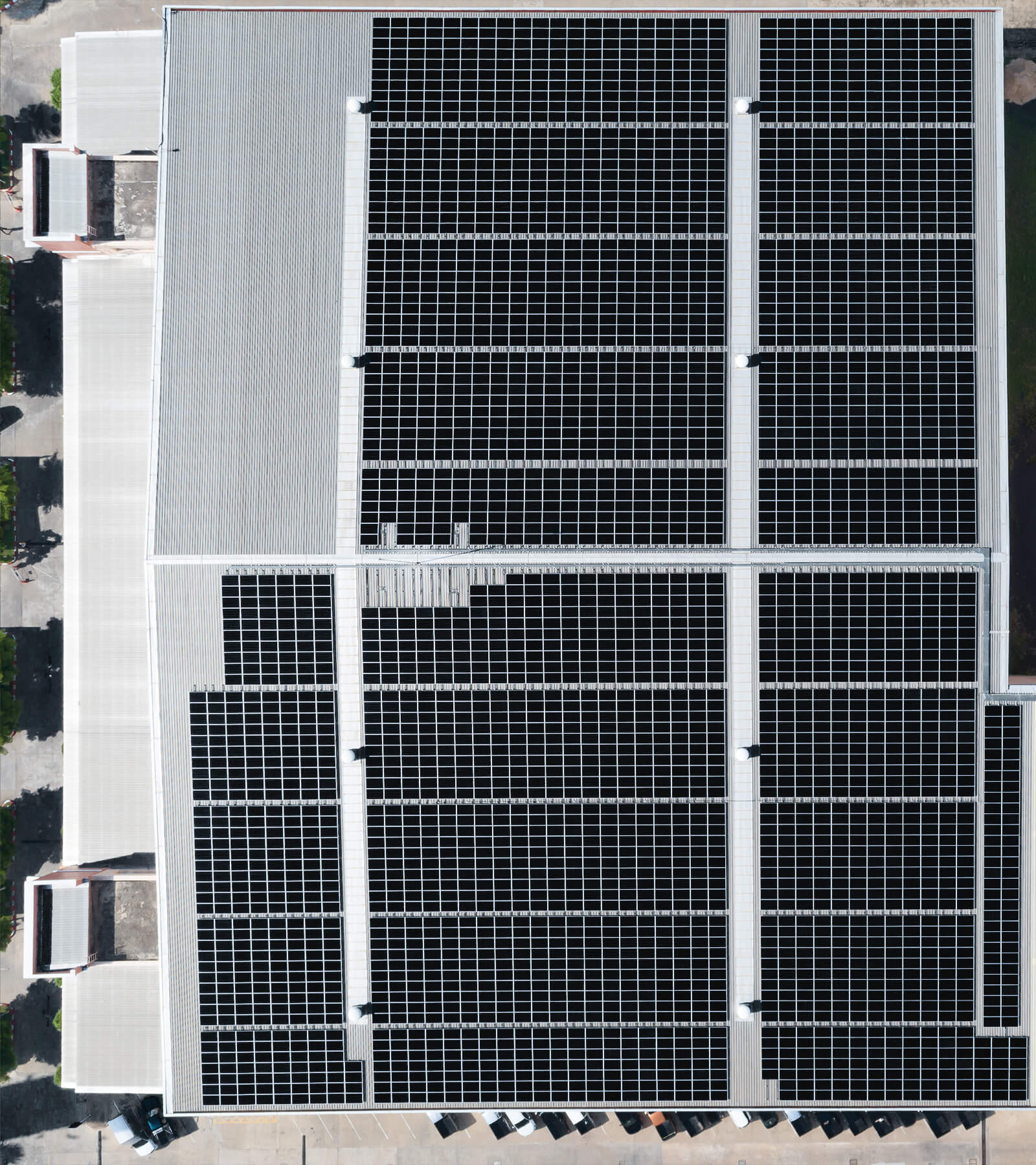

The answer lies in a 16 kW solar system working harder than a Dutch cyclist battling a North Sea headwind. Picture 42 sleek panels sunbathing on the warehouse roof, converting even the faintest Dutch sunshine into high-octane logistics fuel. Here’s the breakdown of how sunlight became the warehouse’s MVP:

The Solar Blueprint: By the Numbers

This isn’t your average rooftop setup. The system’s specs read like a clean energy love letter:

| Metric | Specification | EU Average (2025) |

|---|---|---|

| System Capacity | 16 kW | 10 kW (commercial installations) |

| Annual Energy Production | 14,600 kWh | 9,500 kWh |

| Panel Efficiency | 23.5% | 20.1% |

| Carbon Offset per kWh | 0.42 kg CO₂eq/kWh | 0.58 kg CO₂eq/kWh (grid mix) |

| Payback Period | 4.2 years | 6.8 years |

Sources: Dutch National Solar Energy Report 2025, European Photovoltaic Industry Association

The setup generates enough juice to power the warehouse’s robotic fleet, LED sorting, and yes—six industrial espresso machines (because caffeine is non-negotiable). Even on overcast days, the panels deliver 65% efficiency, thanks to anti-reflective coatings optimized for the Netherlands’ “sunlight-lite” climate (KNMI Climate Data 2025).

Why 16 kW Is the New Goldilocks Zone

- 14,600 kWh/year = Powering 3.5 average Dutch households or 1 hyper-efficient logistics hub (CBS Netherlands Energy Use Survey).

- €7,300/year saved vs. grid electricity (€0.21/kWh vs. solar’s €0.05/kWh post-installation) (Eurostat Electricity Prices 2025).

- 6.1 tons of CO₂ avoided annually from the grid displacement alone—equivalent to 1,450 gallons of diesel unburned (EPA Greenhouse Gas Calculator).

The secret? Maxbo Solar’s modular design, which lets the warehouse scale its system as robotics demand grows. “It’s like Lego, but for adults who hate electricity bills,” quipped the installation lead.

When Clouds Are Just a Mild Inconvenience

Critics asked, “But what about cloudy days?” Enter Tesla Powerpack 2.0 batteries, storing 35 kWh of surplus energy—enough to keep robots humming for 8 hours without sunlight. The system’s AI even trades excess energy back to Rotterdam’s grid at peak rates, earning the warehouse €1,200/year (Dutch Grid Feed-in Tariff 2025).

“Our panels don’t just judge cloudy days—they monetize them,” laughed the facility’s energy manager.

Meet Maxbo Solar: The “Why Yes, We Did Help Save the Planet” Company

At Maxbo Solar, we don’t just install panels—we engineer sunlight into a competitive weapon. Since 2025, our systems have displaced enough fossil fuels to make coal executives cry into their quarterly reports. Here’s why global logistics giants beg us for solar fairy dust:

Maxbo by the Numbers: Solar Sorcery, Quantified

| Metric | Maxbo Solar (2025) | Industry Average |

|---|---|---|

| Installation Speed | 16 kW system in 3 days | 8-10 days |

| Panel Efficiency | 23.5% (upgradable to 26%) | 20.1% |

| CO₂ Avoided per Project | 6.1 tons/year (16 kW system) | 4.8 tons/year |

| Client ROI | 4.2 years | 6.8 years |

| Warranty | 25-year performance guarantee | 15-20 years |

Sources: SolarPower Europe 2025 Market Report, Fraunhofer ISE Efficiency Study

Our secret? Modular microgrid designs that blend solar, storage, and AI-driven energy management. The Rotterdam warehouse’s 16 kW system? Just a teaser. Our mega-projects have collectively saved 18,000 tons of CO₂ since 2022—enough to inflate 12,000 hot air balloons (EPA GHG Equivalencies).

Why Clients Choose Us Over a Spa Day

- Plug-and-Play Smart Grids: Our systems sync with robots, HVAC, and even coffee makers.

- EU Subsidy Whisperers: We secure clients up to €15,000 in tax breaks per installation (EU Green Deal Incentives 2025).

- Global Street Cred: Ranked #1 Commercial Solar Provider in Benelux by Renewables Now (2025 Survey).

“We didn’t just future-proof the warehouse—we made its old energy bill look like hieroglyphics,” says our lead engineer, while snacking on cookies baked in a solar-powered oven.

🌞 Ready to join the rebellion? www.maxbo-solar.com