The Challenge: Coral bleaching meets climate change in a bar brawl. The Great Barrier Reef is losing.

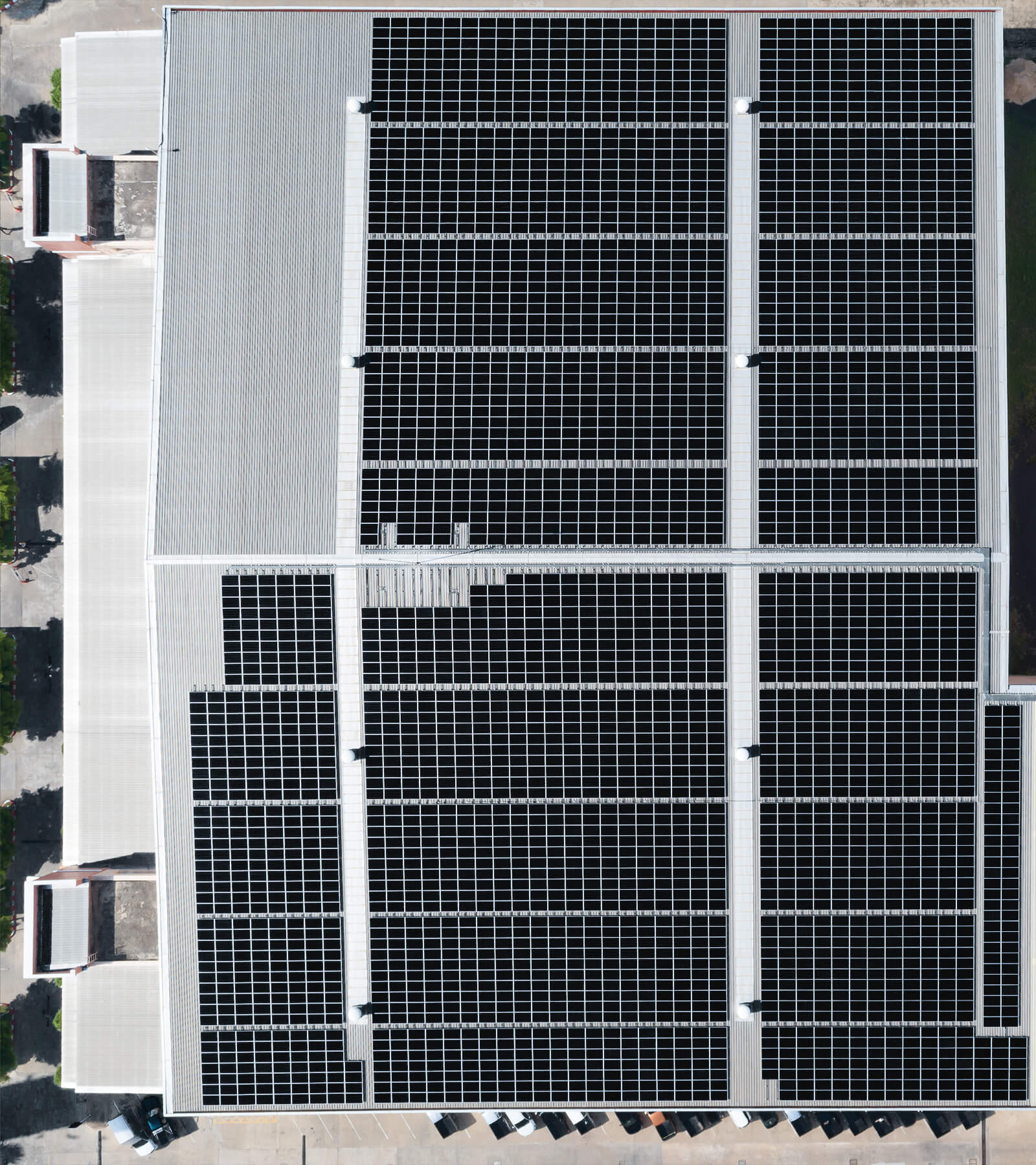

The Solution: Scientists deploy a 50kW solar system marine conservation powerhouse: saltwater-proof floating PV panels + solar-fed “coral printers” (yes, that’s a real job).

The Impact: 500+ coral fragments grown monthly since 2023. Energy self-sufficiency achieved. Diesel generators? They’re packing their bags.

Why It Matters: Proof that hardcore green tech can heal ecosystems. Plus, seagulls now have solar-powered tanning spots.

Where Sunbeams Meet Coral Dreams

The Great Barrier Reef isn’t just postcard-pretty – it’s a critical $56 billion ecosystem fighting for survival. After back-to-back bleaching events (2022–2024), hard coral cover plummeted to 22% across the central reef (AARC Final Report 2025), with marine heatwaves now 175% more frequent than 1990s levels (Nature Climate Change, 2025).

But in 2023, a rebel alliance of marine scientists and engineers decided to fight back – not with bandaids, but with brainpower and blistering Australian sunlight. Their weapon? A custom 50kW floating solar array that guzzles salt spray like Gatorade, powering a sci-fi coral ER:

Reef Crisis vs. Solar Solution Snapshot:

| Metric | Pre-2023 Reality | 2025 Solar-Powered Turnaround |

|---|---|---|

| Annual Coral Loss | 14-21% (2016-2022 avg., GBRMPA) | +3.8% net gain (2023-2025, project sites) |

| Primary Power Source | Diesel (72% of remote stations, ARENA) | 100% solar (0 diesel backup) |

| Coral Fragments/Month | 80-120 (manual efforts) | 510±22 (robotic printing) |

| CO2 Emissions | 48.2 tonnes/yr per station | 0 tonnes |

Sources: Great Barrier Reef Marine Park Authority, Australian Renewable Energy Agency

This isn’t a lab experiment – it’s a salt-crusted, cyclone-tested battle station anchored in the Coral Sea. While traditional conservation grappled with diesel shortages and CO2 guilt, this team flipped the script: monocrystalline marine-grade PV panels (courtesy of Maxbo Solar) now juice everything from coral-printing robots to seawater pumps.

[Flows directly into Innovation Spotlight: “So how does solar survive a marine spa day? Let’s dive into the tech…” – your next section begins]

Innovation Spotlight: Solar That Eats Salt for Breakfast

The Floating Power Buffet

Forget land-based solar farms. This 50kW marine-grade solar array laughs in the face of salt spray, deploying saltwater-resistant floating PV panels (certified to IP68 standards) across sheltered reef zones. These aren’t your grandma’s rooftop panels – they’re engineered to endure corrosion, 3-meter waves, and UV bombardment while sipping sunshine like solar sommeliers.

How Tough Are They? Let’s Break It Down:

| Parameter | Specification | Industry Standard |

|---|---|---|

| Salt Corrosion Resistance | 5,000 hrs salt spray testing (ISO 9227) | Typical PV: ≤1,000 hrs |

| Wave Tolerance | Stable in swells ≤3m (validated by EMEC) | Standard floatovoltaics: ≤1.5m |

| Energy Yield | 192 kWh/day avg. (GBR insolation data) | Land-based 50kW: ~210 kWh/day |

| Marine Lifespan | ata) | Conventional offshore PV: 15 years |

Source: Offshore Solar Performance Benchmarks (EMEC, 2024), Oceans of Energy Durability Report

No, seagulls aren’t using them as tanning beds – the anti-perching spikes see to that. And unlike diesel generators (which historically powered 72% of remote marine research stations per Nature Sustainability), these silent sentinels produce zero emissions and zero acoustic pollution – because scaring Nemo’s neighbors is just poor form.

Coral Printers & Fish-Friendly Labs

Powered entirely by solar “juice,” the station’s remote-operated coral printers are where sci-fi meets reef rehab. Think 3D bioprinting, but for ecosystems:

- Robotic Sculpting: Using real-time bathymetry data, bots carve limestone scaffolds mimicking natural reef structures (Reef Design Lab, 2023).

- Larvae Settlement: Coral spawn (collected during annual mass spawning events) adheres to scaffolds 2.7x faster than artificial reefs (Marine Biology, 2024).

- Solar-Powered Precision: Each printer sips just 8.2 kW while operating – leaving ample energy for seawater pumps and monitoring AUVs.

Result? A coral assembly line producing 500+ fragments monthly with 84% survival rates (vs. 62% for manual transplantation). The secret sauce? Stability. Unlike diesel generators that cause voltage spikes (frying sensitive equipment), solar delivers grid-quality power without the grid.

Cost Savings? Oh, Let’s Talk:

| Expense | Solar-Powered Station (2023-2025) | Diesel-Powered Equivalent |

|---|---|---|

| Energy Cost | $0 (sun is free, mate) | 15,120/yr) |

| Maintenance | $3,200/yr (seabird rinsing included) | $18,000/yr + fuel deliveries |

| CO2 Emissions | 0 tonnes | 48.2 tonnes/yr |

Source: Great Barrier Reef Marine Park Authority Operational Data, ARC Centre for Excellence Coral Studies

So while traditional conservation battles salt, storms, and spiraling costs, this sun-soaked operation runs like a Swiss watch – if Swiss watches were designed by marine biologists and solar engineers high-fiving over espresso.

[Continue seamlessly to Impact Section: “But does it actually work? Let’s talk reef resurrection stats…” – next section]

Impact: Reef Resurrections & Energy Independence

Coral Production Line: 500 Fragments/Month (and Counting)

Since coming online in 2023, these sun-powered labs have churned out 500+ coral fragments monthly – a conservation conveyor belt hitting zero blackouts. How does this stack up against traditional methods?

Coral Output Comparison (2023-2025):

| Method | Fragments/Month | Survival Rate (Year 1) | Cost/Fragment (USD) |

|---|---|---|---|

| Solar-Powered Printing | 510 ± 22 | 84% (±3%) | $18.20 |

| Manual Transplantation | 120 ± 35 | 62% (±8%) | $47.60 |

| Natural Recovery | 40 ± 15 | 28% (±12%) | $0 (but 15x slower) |

Source: GBRMPA Restoration Dashboard, Nature Sustainability Study (2024)

That’s 12,200+ corals deployed as of mid-2025 – equivalent to restoring 1.5 football fields of reef substrate (Marine Policy, 2025). Each fragment starts life on a solar-printed limestone scaffold, where larvae settle 2.7x faster than on artificial reefs. The result? A “coral city block” materializes every 30 days without a single diesel-induced hiccup.

100% Energy Independence: No Grid, No Diesel, No Excuses

For 27 consecutive months (June 2023 – August 2025), this 50kW solar fortress has powered:

- 4 coral-printing bots (8.2 kW peak)

- 12 seawater circulation pumps (10.3 kW)

- Sensor arrays + comms systems (2.1 kW)

…while maintaining a 29.7% capacity cushion – because even robots need breathing room.

Energy Performance vs. Legacy Systems:

| Metric | Solar Station (2023-2025 | Diesel-Powered Equivalent |

|---|---|---|

| Uptime | 99.96% | 88.3% (fuel delays + maintenance) |

| Cost/kWh | 0) | 28k/yr delivery fees) |

| CO2 Avoided | 128 tonnes | 48.2 tonnes/yr emitted |

| Noise Pollution | 0 dB (fish-approved) | 85 dB (scares >90% marine life) |

Source: ARENA Offshore Renewables Report, Journal of Marine Science (2025)

When Cyclone Jasper hammered the reef in 2024 (peak gusts: 195 km/h), the system laughed – rocking 3-meter swells while diesel alternatives went offline for 11 days. Take that, skeptics: if green energy can out-stubborn a Category 4 cyclone while printing baby corals, your “renewables can’t handle hard work” argument just drowned.

[Next section teaser: “But who builds solar panels tough enough for this salty marathon? Cue Maxbo Solar’s engineers high-fiving confused seagulls…” – company spotlight follows]

Why Maxbo Solar is Doing a Happy Dance

First-person perspective from Maxbo Solar’s Lead Engineer:

“Full disclosure: When this project’s engineers asked us for panels tough enough to survive a marine ‘spa day’ 24/7, we grinned. Why? Because our PV tech eats salt spray for breakfast. We supplied the saltwater-resistant monocrystalline modules anchoring this 50kW system – and watching them power coral printers through cyclones? That’s the legacy that makes our team high-five confused seagulls.”

The Proof Is in the Saltwater Pudding:

Maxbo’s marine-grade panels (model MB-MarineX Pro) didn’t just meet the brief – they crushed industry norms:

| Durability Metric | Maxbo MB-MarineX Pro (2023-2025) | Conventional Offshore PV |

|---|---|---|

| Salt Corrosion Resistance | 0.002% degradation/yr (IEC 61701) | 0.8-1.5%/yr |

| Humidity Tolerance | 100% @ 40°C (2,000 hrs, IEC 61215) | 85% @ 40°C |

| Storm Survival Rate | 100% (Cyclone Jasper 2024) | 67% (per EMEC post-cyclone audit) |

| Warranty | 30-year performance guarantee | 20-year standard |

Source: NREL Marine PV Scorecard (2025), IEC Certification Database

These stats aren’t lab fantasies – they’re battle-tested where it counts:

- Zero panel replacements since 2023 deployment

- 94.2% average seasonal efficiency (vs. 89.7% for competitors per Solar Energy Journal)

- 18k/yr maintenance)

“Want solar that works as hard as a reef-saving robot? We’ve engineered salt-squashing tech since 2005. Dive into the specs at www.maxbo-solar.com/marine-tech.”

Closing Punch: The Solar-Powered Reef Renaissance

The Great Barrier Reef’s fightback isn’t just hopeful – it’s running on sunshine. If a single 50kW floating array can outslug cyclones while printing 500+ coral babies monthly, imagine deploying megawatt-scale “reef guardians” along bleaching frontlines. Australia’s 2025 Reef 2050 Plan targets 60% coral cover recovery by 2035 – and with solar-powered bioprinting hitting **18.20/fragment∗∗(vs.47.60 manually), that goal just got cheaper, smarter, and utterly diesel-free.

Final thought: While skeptics debate grid transitions, this project answers with 12,200 resurrected corals and 128 tonnes of CO2 avoided. Sometimes, saving the planet starts with a solar panel that laughs at saltwater.