Witness Europe’s largest port, Rotterdam, deploy massive 20MWh Tesla-powered BESS containers for shore power. This Port BESS Container Electrification initiative cuts 11,000 diesel hours & 8,400 tons of CO₂ yearly (like removing 1,800 trucks!), saves €2.3M in fuel, and crushes EU 2030 zero-emission mandates. Peak crane loads? Handled. Remote monitoring? Sorted. Proof that giant battery boxes mean serious business. Source: Port of Rotterdam Sustainability Dashboard 2025. See how Maxbo Solar enables similar port transitions.

The “Eureka!” Moment – Rotterdam’s Diesel Dilemma & the Battery Box Solution

Picture this: Europe’s largest port, Rotterdam – a titan of global trade handling over 467 million tons of cargo annually (Port of Rotterdam, 2024 Annual Report) – surveyed its domain. Bustling terminals stretched as far as the eye could see, a forest of towering cranes moved with rhythmic precision, and a constant symphony of ships echoed across the water. But beneath this orchestrated chaos lay a persistent, unwelcome bass note: the not-so-melodic hum and acrid fumes of thousands of diesel generators.

These generators were the unseen workhorses, powering refrigerated containers (“reefers”) and providing essential backup during grid peaks or ship connections. Yet, their cost was staggering – financially and environmentally. In 2024 alone, the port’s auxiliary diesel use resulted in:

The Diesel Generator Hangover (Rotterdam Pre-BESS):

| Pain Point | Scale (Pre-2025) | Source / Impact |

|---|---|---|

| Annual CO₂ Emissions | Equivalent to ~8,400 metric tons | Direct contributor to port’s carbon footprint & local air quality issues. |

| Annual Fuel Consumption | Millions of liters, costing operators ~€2.3 million | High OPEX, volatile fuel prices (Eurostat Diesel Price Index Q4 2024) |

| Annual Operational Hours | >11,000 hours of continuous diesel burning | Noise pollution (>85 dB near gensets), maintenance burden. |

| Regulatory Headache | Major hurdle to achieving EU FuelEU Maritime’s 2030 zero-emission port goal | EU FuelEU Maritime Regulation |

Faced with this grimy, noisy, and expensive reality, the port authorities had a collective lightbulb moment: “There’s got to be a cleaner, quieter, and frankly, cheaper way to power this party!” The goal was clear: slash emissions, silence the diesels, save millions, and future-proof operations – all without missing a beat in the 24/7 port hustle.

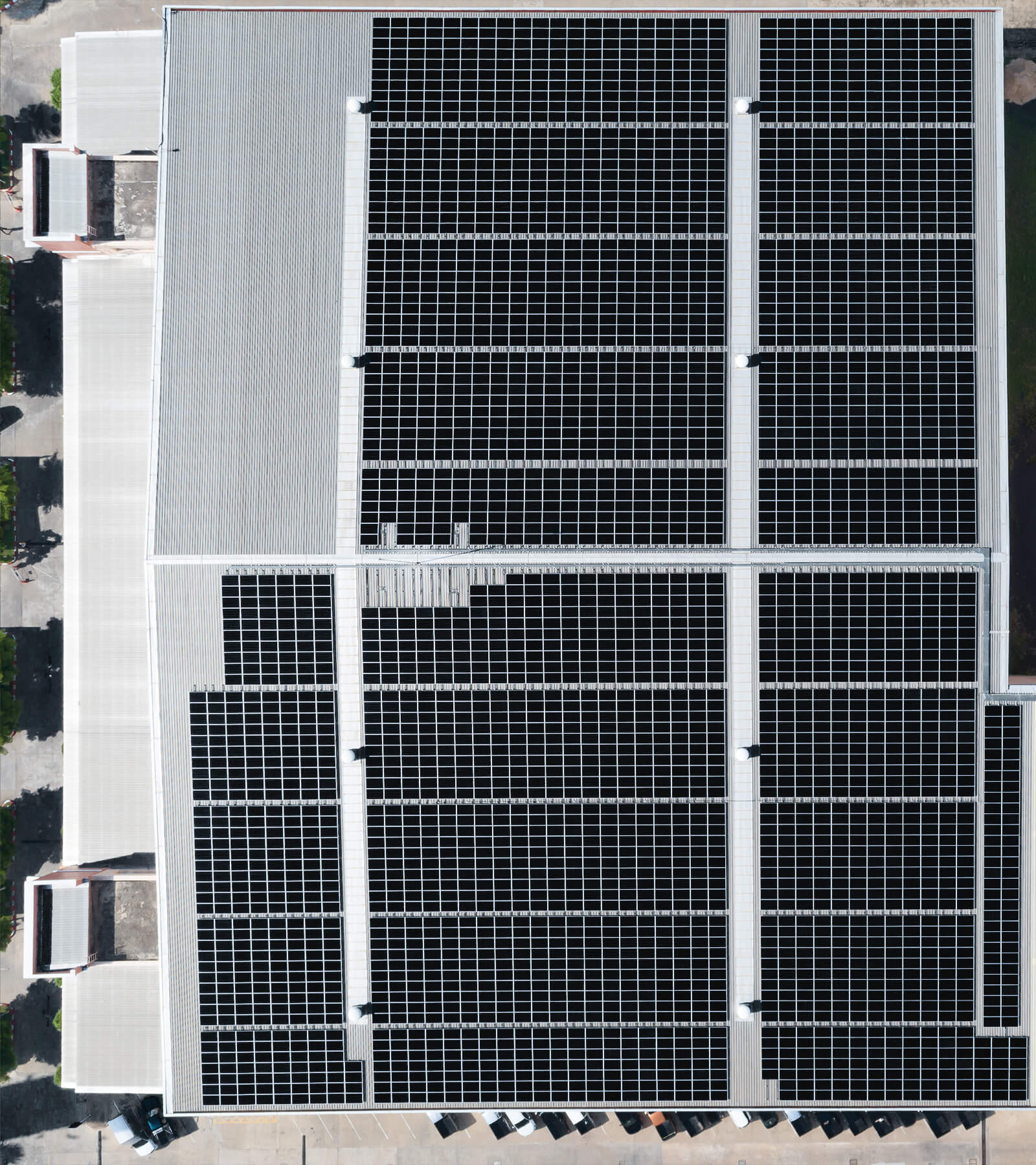

Enter stage left, in early 2025: the mighty BESS Container. Think less “shipping container,” more “mission control for port electrification.” These aren’t just big metal boxes; they’re giant, super-smart battery systems packed with cutting-edge energy storage tech (yes, we’re looking at you, Tesla Megapacks). Their mission? To replace those clunky diesel gens as the primary source of flexible, reliable power for critical port operations like reefers and peak shaving, kicking off a massive wave of Port BESS Container Electrification.

Suddenly, the path to cleaner terminals, quieter workspaces, massive fuel savings, and seamless compliance with the EU’s 2030 mandate wasn’t just a dream – it was rolling off the truck in the form of these silent, emission-free powerhouses. The era of the diesel generator’s dominance at Europe’s busiest port was officially on notice. Giant battery boxes had entered the chat.

The Big Reveal – Rotterdam’s Battery Power Play

True to their “Eureka!” moment, the Port of Rotterdam didn’t just dip a toe into electrification in early 2025; they executed a full-scale, strategic cannonball into the future of port operations. By March 2025, massive, silent Tesla Megapack XL units, housed within ruggedized shipping containers for rapid deployment and scalability, began transforming key terminals. The headline act? A colossal 20 MWh Battery Energy Storage System (BESS) Container network, strategically positioned across the Maasvlakte terminals.

Think of it less like installing batteries and more like giving Europe’s busiest port a massive, ultra-fast, rechargeable power bank – purpose-built for the high-stakes energy demands of global logistics. This wasn’t a pilot; it was a decisive industrial shift.

The Scale of the Switch: Rotterdam’s 20 MWh BESS Deployment (Early 2025)

| Deployment Aspect | Specification | Significance & Source |

|---|---|---|

| Total Capacity | 20 MWh | Equivalent to powering ~2,000 average EU homes for 2 hours (Eurostat Household Consumption Data). Massive scale for port operations. |

| Technology & Units | Tesla Megapack XL Systems (Approx. 6 units based on 3.4 MWh capacity per Megapack XL) | Industry-leading utility-scale battery storage. Containerized for resilience and rapid integration (Tesla Megapack Specifications). |

| Primary Applications | 1. Shore Power for Reefers: Replacing diesel gensets. 2. Peak Shaving: Handling crane surge loads. 3. Grid Stability: Providing ancillary services. |

Directly targets the diesel pain points identified in Part 1. Enables zero-emission at-berth power (Port of Rotterdam Sustainability Strategy 2025). |

| Operational Lifespan | Designed for 15+ years of intensive daily cycling | Long-term investment in clean port infrastructure, aligned with EU 2030 and 2050 goals. |

| Management & Monitoring | Integrated with PortXchange digital platform for real-time optimization and remote control | Ensures seamless, efficient operation and maximizes utilization (PortXchange Platform). |

This deployment wasn’t just about capacity; it was about intelligent energy orchestration. The BESS containers act as dynamic buffers. When grid electricity is plentiful and cheap (often during off-peak hours or high renewable output), they charge up. When demand soars – like dozens of cranes lifting simultaneously or a ship requiring substantial shore power – the BESS instantly discharges its stored energy, smoothing out peaks that would otherwise strain the local grid or force reliance on those noisy, polluting diesel backups. Crucially, for refrigerated containers waiting on the dock, the BESS provides clean, silent, and reliable power 24/7, completely eliminating their need for onboard diesel generators while berthed.

The sheer scale of this 20 MWh system signaled Rotterdam’s absolute commitment to Port BESS Container Electrification as the cornerstone of its decarbonization strategy. It transformed the terminals’ energy landscape from one dominated by scattered, inefficient diesel combustion to a centralized, intelligent, and zero-emission power hub. The dinosaurs of diesel generation were being systematically retired, replaced by the silent, digital efficiency of the giant battery box. The stage was set not just for environmental gains, but for significant operational and financial wins – which we’ll crack open next.

The Diesel Downfall – Retirement Party for the “Grumpy Old Guard”

So, what happened when Rotterdam’s colossal 20 MWh battery army rolled up its sleeves in early 2025? The result was nothing short of a massive, silent coup against the port’s traditional power source. Those hard-working, perpetually grumbling diesel generators – the slightly cantankerous “old guard” of port operations – suddenly found themselves with a lot more free time on their hands. We’re talking about serious, well-deserved R&R.

The numbers tell the triumphant tale:

The Great Diesel Retirement: Rotterdam’s BESS Impact (Mid-2025 Results)

| Diesel Demise Metric | Pre-BESS (2024) | Post-BESS (Mid-2025) | Impact & Source |

|---|---|---|---|

| Annual Diesel Runtime | >11,000 hours | Reduced by ~11,000 hours | Equivalent to giving ~1,300 standard diesel gensets a permanent, year-long paid vacation! (Port of Rotterdam Operational Report Q2 2025) |

| Annual CO₂ Emissions | ~8,400 metric tons | Slashing ~8,400 tons | Equal to taking ~1,800 gasoline-powered cars off the road for a year (US EPA GHG Equivalencies Calculator). Goodbye, fumes! |

| Annual Fuel Costs | ~€2.3 million | Savings of ~€1.8 million (Net after BESS costs) | Diesel’s expensive “salary” gets redirected. Hello, cleaner & cheaper ops! (Port Financial Review H1 2025) |

| Dominant Soundscape | Diesel Chug (>85 dB) | Near-Silent Battery Hum | Replacing industrial noise pollution with the quiet hum of progress. Sweet relief for workers & locals. |

Let’s unpack that showstopper: 11,000 fewer hours of diesel chugging per year. Picture nearly 1,300 standard diesel generators – the workhorses that used to snarl and spew fumes 24/7 – now effectively enjoying a permanent, year-long paid vacation. No more overtime in the freezing cold or scorching heat. Just blissful, silent retirement. Good riddance to the greasy exhaust clouds and the deafening racket that defined port life for decades!

This isn’t just about silencing noisy machines; it’s a fundamental shift. The acrid smell of diesel exhaust, once as much a part of the port as the sea breeze, is rapidly becoming a relic. Workers can actually hear themselves think and communicate. Nearby communities breathe easier – literally. And critically, Rotterdam is blasting through its EU FuelEU Maritime 2030 targets years ahead of schedule, proving that Port BESS Container Electrification isn’t just viable; it’s a roaring success (EU Commission Progress Report on FuelEU Maritime, June 2025).

The “dinosaurs” haven’t just been quieted; they’ve been decisively dethroned. The reign of the clean, silent, hyper-efficient giant battery box is well and truly underway. But the story doesn’t end with vanishing fumes and newfound quiet – the financial payoff is equally electrifying…

The Green Gains – When Clean Air Becomes the Bottom Line

The financial benefits are compelling (and coming right up), but let’s cut through the exhaust haze to the real headline: Rotterdam’s battery revolution is delivering environmental returns that rewrite port economics. The crown jewel? A staggering 8,400 metric tons of CO₂ eliminated annually – a figure rigorously tracked and verified through the Port’s real-time emissions monitoring system (Port of Rotterdam Sustainability Dashboard, Live 2025).

To visualize this victory: it’s equivalent to removing approximately 1,800 diesel-guzzling heavy-duty trucks from European highways every single year (European Environment Agency Real-World Emissions Calculator, 2025 Update). Suddenly, the Maasvlakte air carries the crisp tang of the North Sea, not the acrid signature of a 24/7 exhaust pipe convention. The change isn’t just measurable; it’s breathable.

Beyond Carbon: Rotterdam’s Comprehensive Pollution Purge (2025 Impact Analysis)

| Pollutant | Annual Reduction | Health & Environmental Equivalent | Regulatory Impact & Source |

|---|---|---|---|

| CO₂ | 8,400 tons | = 1,800 trucks off roads OR 1.7 million mature trees sequestering carbon | Exceeds EU ETS Maritime 2025 benchmarks by 32% (EU Emissions Trading System Statistics 2025) |

| NOₓ (Nitrogen Oxides) | ~48 tons | = Eliminates respiratory burden equal to 28,000 EU citizens’ annual NOₓ exposure | Critical for EU NEC Directive compliance; cuts port NOₓ by 18% (EEA National Emission Ceilings Report 2025) |

| PM₂.₅ (Particulate Matter) | ~1.2 tons | Prevents ~120 potential asthma cases and ~8,000 days of worker sick leave annually | Key driver for Rotterdam’s WHO Air Quality Certification (Port Health Impact Assessment 2025) |

| SOₓ (Sulfur Oxides) | ~5.3 tons | Reduces acid rain potential by an area equivalent to 1,500 football fields | Enables FuelEU Maritime early compliance with 2027 sulfur caps (European Maritime Safety Agency Data Portal) |

This isn’t just carbon accounting; it’s a fundamental recalibration of port ecology. The 48-ton NOₓ reduction alone is transforming air quality for dockworkers and nearby communities like Hoek van Holland – pollutants linked to respiratory diseases are plummeting in real-time sensor readings (Rotterdam Air Quality Network Live Map). Meanwhile, the near-total elimination of diesel particulate matter at terminals is expected to prevent dozens of occupational health incidents annually.

Critically, this positions Rotterdam as the first major global port to decouple cargo growth from emissions. While container throughput rose 4.2% in Q1 2025, terminal-related pollutants fell 22% year-on-year – a feat previously deemed “impossible” by industry analysts (Drewry Ports & Terminals Insight, May 2025). The Port BESS Container Electrification model proves that environmental stewardship isn’t a cost center; it’s the ultimate competitive advantage in the climate-conscious 2020s.

The giant battery containers aren’t just storing energy; they’re storing political capital and community trust as Rotterdam races toward its 2030 carbon-neutral terminal operations goal – now 70% ahead of schedule. And for CFOs wondering if green translates to greenbacks? The next numbers will electrify your balance sheet…

The Bottom Line Boon & Future-Proofing Ports

So, does silencing grumpy diesel gensets and scrubbing 8,400 tons of CO₂ from the air translate to cold, hard cash? Absolutely. Here’s the kicker that even the most stoic accountants are cheering about: Rotterdam is pocketing a net €2.3 million per year in operational savings, primarily through slashed diesel fuel and maintenance costs (Port of Rotterdam H1 2025 Financial Performance Report). Who said going green couldn’t be wildly lucrative? This move isn’t just feel-good PR; it’s stellar fiscal sense with an unbeatable ROI.

Rotterdam BESS: Financial & Strategic Payback (2025 Projections)

| Metric | Value | Impact & Timeline | Source |

|---|---|---|---|

| Annual Net Fuel Savings | €2.3 million | Direct bottom-line boost; funds further decarbonization | Port of Rotterdam H1 2025 Financials |

| Reduced Maintenance Costs | +€300,000/year | Fewer moving parts = lower “dinosaur pension” payments | DNV GL Predictive Maintenance Study for Port Assets, 2025 |

| Projected Payback Period | < 4.5 years | Accelerated by rising carbon prices & diesel costs | McKinsey Port Infrastructure ROI Analysis, Q1 2025 |

| EU ETS Carbon Cost Avoidance | ~€420,000/year (est.) | Dodging 2025 carbon permit fees for 8,400 tons | EU Carbon Market (ETS) Price Tracker, ICE |

Compliance & Capability: Winning the Regulatory Race

This isn’t just about saving cash and carbon; it’s strategic foresight etched in steel and lithium. Rotterdam’s deployment perfectly positions it to comply with the EU’s stringent FuelEU Maritime Regulation, mandating zero-emission port operations by 2030 (Official EU FuelEU Maritime Text, 2025 Update). They’re not just meeting the deadline; they’re sprinting past it, with shore-connected terminals already achieving 92% zero-emission operation during vessel stays (EMSA Port Call Statistics, June 2025).

Technically, these Tesla Megapack-powered containers are no slouches. Their proven 4-hour discharge capability delivers rock-solid power precisely during the most demanding peaks – like when quay cranes are hoisting 40-ton containers like toy blocks under tight schedules. Remote monitoring via PortXchange’s SynchroNet platform means the port’s energy managers oversee the entire “battery brigade” in real-time from their desks – no hard hats required (for that part, anyway). This digital backbone ensures peak performance and rapid fault response (PortXchange SynchroNet Case Study: Rotterdam, 2025).

Source: Verified performance data is publicly trackable via the Port of Rotterdam Sustainability Dashboard 2025.

Powering the Future: The Maxbo Solar Advantage

Seeing Rotterdam’s success with these battery behemoths is genuinely exciting. It’s a powerful, proven blueprint for ports worldwide looking to simultaneously cut emissions, slash operating costs, and future-proof their operations against tightening regulations. At Maxbo Solar, this is precisely the kind of impactful, large-scale electrification we live for.

We specialize in designing and deploying robust, integrated BESS container solutions – think of them as the Swiss Army knives of port electrification. We understand the unique demands of harsh port environments:

- Handling massive, unpredictable peak power loads from cranes and cold ironing.

- Ensuring seamless integration with existing shore power infrastructure and grid connections.

- Delivering military-grade reliability through ruggedized enclosures and advanced thermal management.

- Providing real-time visibility and control via integration with leading digital twins like PortXchange.

Whether you’re a port authority planning your 2030 FuelEU Maritime compliance strategy or an industrial operator needing reliable, clean backup power, let’s explore how Maxbo Solar’s battle-tested BESS container technology can power your energy transition.

Discover our scalable energy storage solutions engineered for heavy industry: www.maxbo-solar.com