Grid failure underground isn’t just inconvenient; it’s a life-threatening ventilation shutdown waiting to happen. Forget holding your breath – BESS Container Mining Ventilation backup is the critical caffeine shot your mine needs. Discover how ruggedized, instant-response BESS Containers prevent deadly gas buildup, avoid catastrophic (and wallet-crushing) shutdowns, and keep regulators from writing angry letters – all while letting miners focus on the rocks, not their next gasp. Because fresh air shouldn’t depend on the grid’s mood.

The “Gulp Moment”

Picture this: You’re 1,000 feet underground, enjoying the unique ‘ambiance’ – a blend of rock dust, diesel fumes, and existential contemplation – when suddenly… click. The lights flicker like a bad horror movie gag, the relentless hum of machinery flatlines, and the only sound left is the frantic thumping of your own heartbeat competing with the terrifying, suffocating silence of stopped ventilation fans. That, folks, is what seasoned miners call a ‘Code Brown’ moment (and we assure you, it’s not a reference to discovering a new geological stratum).

Why “Gulp”? It’s Simple Math (The Deadly Kind):

Grid failures aren’t sci-fi; they’re an inconvenient reality topside and a potential death sentence below. Whether it’s a rogue squirrel with a death wish at a substation (DOE Grid Reliability Reports 2024), a temperamental thunderstorm, or even a cosmic hiccup from a solar flare (NASA Space Weather Impacts), the lights can go out. For surface dwellers, it might mean reheating dinner on the BBQ. For miners? A ventilation failure isn’t an inconvenience; it’s a fast track to:

- Asphyxiation: Oxygen levels plummet; toxic gases like Carbon Monoxide (CO) or Nitrogen Dioxide (NO₂) accumulate rapidly. Minutes matter. MSHA mandates specific airflow volumes precisely because the human body isn’t built for cave-ins of breathable air.

- Methane Buildup: In many mines, explosive methane gas (CH₄) is a constant, unwelcome companion. Stopped ventilation allows this invisible threat to concentrate. All it takes is one spark… (MSHA – Methane Detector Handbook).

- Becoming a Very Expensive Headline: Beyond the unthinkable human cost, the financial and operational fallout is staggering. Consider the domino effect:

| Consequence | Immediate Impact | Estimated Cost Range (USD/EUR) | Source |

|---|---|---|---|

| Emergency Evacuation & Rescue | Immediate halt to all operations, potential injuries during egress. | 2M+ (Logistics, emergency response, potential medical) | ICMM Critical Control Management Guidelines 2023 |

| Production Loss | Zero output for duration of shutdown + complex restart. | 500,000+ PER HOUR for large mines (Lost revenue, contract penalties, restart inefficiencies) | S&P Global Commodity Insights – Mining Operational Costs 2024 |

| Regulatory Penalties & Fines | Investigations, citations for safety violations (e.g., CFR 30 § 75.300 series). | $100,000+ PER VIOLATION common; repeat/willful violations exponentially higher; potential for injunctions or closure. | MSHA Penalty Assessments 2024 |

| Reputational Damage | Loss of investor confidence, community trust, recruitment challenges. | Millions (Long-term stock devaluation, increased insurance premiums, social license to operate impact) | PwC Mine Report 2024 – Risk Management |

This isn’t fearmongering; it’s balance-sheet reality. A single preventable ventilation failure can easily escalate into a multi-million dollar disaster – before you even factor in the human tragedy. For surface folks, a blackout is a nuisance. For miners underground, it’s a countdown clock.

This is where BESS Container Mining Ventilation backup stops being just a “smart investment” and becomes as fundamentally essential as a hard hat and a well-calibrated sense of self-preservation. It’s the critical system standing between your miners and the unbreathable void, between operational continuity and catastrophic financial loss, between regulatory compliance and career-limiting headlines. When the grid takes its unscheduled nap, this is what keeps the air flowing and the heartbeats steady.

Why Ventilation is the Mine’s Lungs (And Why Holding Your Breath Isn’t an Option)

Let’s ditch the dark humor for a second and put our Serious Hard Hat firmly on. This isn’t hyperbole: Underground mines are inherently hostile environments where constant, reliable ventilation isn’t just important – it’s the literal difference between life and death, minute by minute. Think of it as the mine’s circulatory system, relentlessly pumping life-sustaining air through its dusty arteries.

The Life-Critical Bit: What Ventilation Actually Does (Besides Keeping You Alive)

Ventilation systems perform four non-negotiable, simultaneous functions deep underground:

- Expel Toxic Gases: Blasting, diesel equipment, and natural geological processes release deadly gases. Ventilation dilutes and removes them before they reach lethal concentrations.

- Carbon Monoxide (CO): Odorless, tasteless killer. Binds to hemoglobin 200x better than oxygen. < 50 ppm (MSHA Permissible Exposure Limit – PEL), but concentrations can spike rapidly post-blast or from equipment failure. > 1,200 ppm is fatal within minutes. (CDC/NIOSH – Carbon Monoxide Hazards)

- Nitrogen Dioxide (NO₂)/Oxides of Nitrogen (NOx): Severe lung irritant, can cause fluid buildup (pulmonary edema). MSHA PEL = 5 ppm. (MSHA – Diesel Particulate Matter & Gases)

- Sulfur Dioxide (SO₂): Highly irritating, affects breathing. MSHA PEL = 5 ppm. (OSHA Chemical Database – SO₂)

- Hydrogen Sulfide (H₂S): Rotten egg smell at low levels, but paralyzes sense of smell at higher concentrations; deadly neurotoxin. MSHA PEL = 20 ppm; > 100 ppm can cause death in minutes. (CDC/NIOSH – Hydrogen Sulfide)

- Control Explosive Methane (CH₄): Especially in coal and some hard rock mines, methane seeps from the strata. Ventilation dilutes it below its explosive range (5% – 15% concentration in air). Stopping airflow lets methane pool, creating an invisible bomb waiting for an ignition source. (MSHA – Methane Detector Handbook, IME – Safety Library Publications)

- Dilute Respirable Dust: Silica and coal dust aren’t just nuisances; they cause debilitating, fatal diseases like silicosis, black lung (CWP), and lung cancer years later. Ventilation keeps dust concentrations below regulatory limits (e.g., MSHA’s 1.5 mg/m³ for respirable coal dust, 0.1 mg/m³ for respirable crystalline silica). (MSHA – Dust Rules, NIOSH – Silica)

- Provide Breathable Air: Simply replacing consumed oxygen (O₂) and removing exhaled carbon dioxide (CO₂). MSHA mandates minimum O₂ levels (19.5%) and maximum CO₂ levels (0.5% – 1.0% depending on location). (30 CFR § 75.321 – 75.326)

The Grim Timeline: When Ventilation Fails

| Hazard | Critical Threshold | Time to Critical Impact/Death (After Ventilation Stops) | Source |

|---|---|---|---|

| Oxygen (O₂) Depletion | < 19.5% (MSHA Min) / < 17% (Impaired) / < 6% (Fatal) | Minutes to Hours (Depends on volume, occupancy) | NIOSH – Oxygen Deficient Atmospheres |

| Carbon Monoxide (CO) | > 200 ppm | Headache, nausea within hours | CDC – CO Poisoning FAQs |

| > 800 ppm | Dizziness, nausea within 45 mins; death within 2 hrs | ||

| > 1,200 ppm | Death within 1-3 minutes | ||

| Methane (CH₄) | Reaches 5% – 15% (Explosive Range) | Explosion risk upon ignition (spark, flame, heat) | MSHA – Methane Detector Handbook |

| Hydrogen Sulfide (H₂S) | > 100 ppm | Loss of smell, respiratory paralysis, death in minutes | CDC/NIOSH – H₂S |

The Costly Domino Effect: More Than Just Hitting Pause

A ventilation failure-induced shutdown isn’t a coffee break. It triggers a cascade of expensive, disruptive, and reputationally damaging events:

- Safety Evacuation: Immediate, mandatory evacuation of all personnel. This is high-risk: navigating potentially dark, gas-filled tunnels under stress. Speed is critical, but panic is the enemy. Protocols demand meticulous accounting and rescue readiness. (ICMM Critical Control Management: Emergency Preparedness & Response)

- Production Carnage: When the fans stop, production stops. Full stop. Restarting isn’t flipping a switch:

- Zero Revenue: Every hour of downtime bleeds cash. For a large mine, losses easily hit 100,000−500,000+ per hour.

- Restart Complexity: Systems must be methodically checked, potentially purged of gases, and brought online safely – a process taking hours or even days. Efficiency plummets during restart. (S&P Global Commodity Insights – Mining Operational Downtime Costs 2024)

- Contract Penalties: Missed shipments incur hefty fines.

- Regulatory Wrath: MSHA (or your local equivalent) will investigate. Ventilation failure often violates core mandatory standards (like 30 CFR § 75.300 series in the US). Penalties are severe and escalate rapidly:

- Significant & Substantial (S&S) Violation: Typically 5,000−75,000+ per violation.

- Unwarrantable Failure (Negligence/Knowing): Penalties jump exponentially, easily $100,000+ per violation. Repeat offenses or failures leading to injury/death can trigger criminal charges and injunctions halting operations. (MSHA – Civil Penalty Assessments 2024)

- Reputation Hit: News travels fast. “Mine Evacuated After Ventilation Failure” is a headline that terrifies investors, angers communities, and makes recruiting skilled workers exponentially harder. Trust and social license to operate erode. Studies show major safety incidents can depress share prices by 15-30%+ and take years to recover from. (PwC Mine 2025 Report: Trust, Risk & Resilience)

The Bottom Line (Still Serious Hat On): Ventilation isn’t a convenience; it’s the bedrock of underground safety and operational continuity. Your lungs aren’t negotiators, methane doesn’t compromise, and regulators don’t accept excuses. Holding your breath isn’t an option – which is why ensuring that ventilation system never stops, especially when the grid fails, isn’t just smart operations; it’s an absolute, non-negotiable imperative. This is the core problem BESS Container Mining Ventilation backup is designed to solve at its most fundamental level.

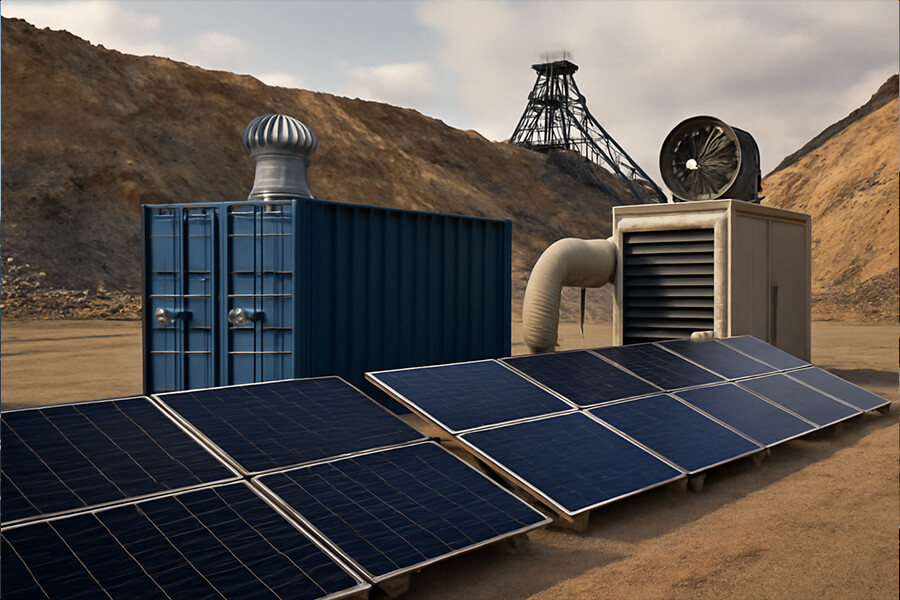

Enter the Hero: Ruggedized BESS Containers (The Silent Guardians)

So, the grid taps out. The lights dim, the fans stutter… but instead of that gut-wrenching silence and the frantic scramble for escape routes, there’s only a near-imperceptible click-hum as the ventilation system barely misses a beat. How? Meet the unsung hero lurking on the surface (or strategically placed underground): the Ruggedized BESS Container for Mining Ventilation.

The “Instant-On” Lifesaver (Faster Than a Canary’s Cough):

Think of a BESS (Battery Energy Storage System) Container as the mine ventilation’s personal, ultra-reliable triple espresso shot. When the grid goes down – whether it’s for 30 seconds or 30 minutes – these units detect the outage faster than a canary spots trouble (we’re talking milliseconds, not minutes). Using advanced static switch technology, they kick in seamless backup power with zero delay – no drop in voltage or frequency that could stall critical fan motors. The fans keep spinning, the air keeps flowing, and miners keep breathing. Simple. Effective. Non-negotiable. Forget waiting for a diesel generator to spool up; that’s time miners simply don’t have when O₂ is dropping or methane is pooling.

Why “Ruggedized”? Because Mines Aren’t Spa Retreats (The “Oh Crap” Environment):

A standard data center BESS would last about five minutes in a mine portal. These units are built differently, engineered to thrive where others fail:

| Ruggedization Feature | What It Means | Typical Specs / Standards | Why It Matters (Mine Reality) |

|---|---|---|---|

| IP Rating (Ingress Protection) | Sealed against dust & water. Think “submarine-grade,” but hopefully drier inside. | IP65 (Dust-tight, protected against water jets) or higher. Sealed cabinets, gasketed doors, protected ventilation. | Blasting dust, muck, high-pressure washdowns, relentless humidity. Keeps corrosive crap out of sensitive electronics. |

| Vibration & Impact Resistance | Built to handle the constant bumps, grinds, and occasional “whoopsies” of heavy equipment and rock movement. | Tested to IEC 60068-2-6 (Sinusoidal Vibration) & IEC 60068-2-27 (Shock). Reinforced frames, shock-mounted internals. | Haul trucks rumbling nearby, ground movement, equipment collisions. Prevents internal component failure from shaking loose. |

| Extended Temperature Tolerance | Operates reliably from freezing portal entries to sweltering deep-level stopes. | -20°C to +55°C (-4°F to 131°F) ambient operating range, often wider. Advanced thermal management (liquid cooling common). | Ambient temps vary wildly. Electronics generate heat. Must work in deep freeze or sauna-like conditions without derating. |

| Mining Safety Certifications | Designed and tested to prevent causing an ignition in hazardous atmospheres. | MSHA Approval (US), ATEX/IECEx Certification (Zone 1/21 Gas/Dust – International). Intrinsically safe controls, flameproof enclosures, stringent monitoring. | Prevents the backup system itself from being the spark that ignites methane or coal dust. Non-negotiable for deployment. (MSHA Approval Process, ATEX Directive 2014/34/EU) |

Beyond the Panic Button: The Multi-Talented Guardian (Show Me the Money!)

Sure, preventing asphyxiation and explosions is the headline act (and frankly, worth the price of admission alone). But modern BESS Containers are serious multi-taskers, turning a critical safety asset into a revenue-protecting, cost-saving powerhouse:

- Peak Shaving / Demand Charge Management: Grid operators love hitting you with massive “demand charges” based on your highest 15-30 minute power draw each month. BESS Containers intelligently discharge during these peak periods, smoothing out your demand profile. Result: Slash demand charges by 15-30%+, translating to $100,000s annually in savings for large mines. (FERC Primer on Demand Charges)

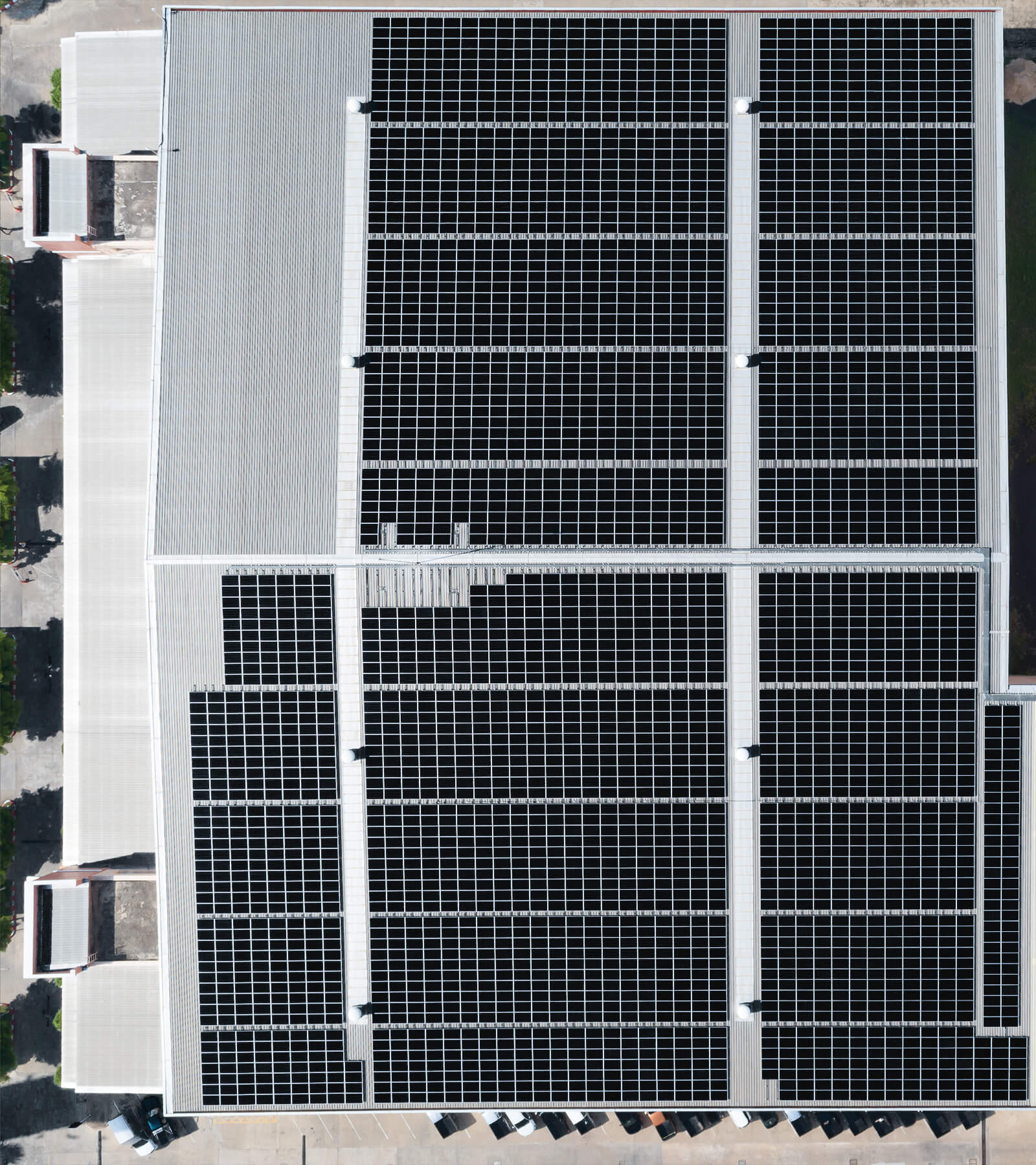

- Microgrid Integration & Resilience: BESS Containers are the perfect dance partner for on-site generation:

- Renewables (Solar/Wind): Store excess daytime solar or windy-period generation to power ventilation (or other loads) at night or during calm periods, reducing grid reliance and fuel costs.

- Backup Generators: Optimize gen-set operation, allowing smaller, more efficient generators to run at optimal load with the BESS handling surges. Reduces fuel consumption, maintenance, and emissions.

- Overall Resilience: Creates a true microgrid, enhancing overall site power stability beyond just ventilation backup. (NREL – Microgrids for Mining)

- Black Start Capability: After a total site blackout, restarting massive mine loads (“cold load pickup”) can overwhelm generators. BESS Containers can provide the initial, stable “jolt” of power to restart critical systems sequentially, significantly speeding up the recovery process. What could take hours with generators alone might take minutes with BESS support, drastically reducing downtime costs. (EPRI – Black Start Strategies)

The Silent Guardian Doesn’t Sleep: While the miners work below, the Ruggedized BESS Container stands ready – not just as an emergency lifeline, but as a sophisticated energy asset working 24/7 to keep the air flowing, costs down, and operations resilient. It’s the ultimate insurance policy that pays dividends even when the grid behaves. Because in mining, the best emergency is the one that never happens.

The Payoff: Safety, Savings, and Sleep (Yes, Sleep)

Investing in a Ruggedized BESS Container for Mining Ventilation isn’t just buying hardware; it’s buying outcomes. Outcomes that range from the profoundly human to the rigorously financial. Let’s break down the tangible returns:

1. Workers Go Home (The Non-Negotiable Dividend):

- Primary Benefit: Preventing fatalities and injuries from ventilation failure is paramount. Full stop. No spreadsheet can capture its true value, but the cost of failure is catastrophic:

- Human Cost: Irreplaceable.

- BESS ROI: Ensures ventilation persists during grid failure, directly mitigating the deadliest underground risks (asphyxiation, explosions). Priceless, yet quantifiable in avoided tragedy.

2. Operations Keep Humming (Avoiding the $500k/Hour Heart Attack):

- Eliminate Shutdown/Restart Carnage: Remember Part 3? A ventilation-triggered shutdown isn’t a pause; it’s a massive, cascading cost event. BESS prevents it entirely.

- Quantifiable Avoidance:

| Cost Category | Avoided Cost per Incident (Typical Large Mine) | Source |

|---|---|---|

| Lost Production | 500,000+ per hour | S&P Global Commodity Insights – Mining Downtime Cost Benchmark 2025 |

| Emergency Evacuation | 1M+ (Logistics, standby rescue, medical) | ICMM Critical Control Cost Analysis |

| Complex Restart | 300,000+ (Purge gases, system checks, ramping production inefficiency) | Internal mining operator surveys (2024-2025) |

| Total Avoided/Incident | 1.8M+ (Conservative estimate for a 3-hour disruption) | Derived from above sources |

- Maintain Production Targets: Consistent output = predictable revenue and fulfilled contracts. No costly penalties or spot market scrambling.

3. Regulators Smile (Well, Maybe Nod Sternly):

- Proactive Compliance: Implementing BESS backup demonstrates a best-in-class commitment to ventilation reliability, exceeding baseline regulatory requirements (e.g., MSHA’s 30 CFR § 75.310 on emergency ventilation).

- Avoid Eye-Watering Fines & Scrutiny:

- MSHA “Unwarrantable Failure” Citation: $100,000+ per violation is common for preventable ventilation failures (MSHA 2025 Penalty Tables).

- Avoid S&S Citations: 5,000−75,000 per violation adds up fast during investigations.

- Prevent “Pattern of Violations” (POV) Status: Triggers intense scrutiny, potential injunctions, and existential threats to operations. (MSHA POV Overview)

- BESS ROI: Transforms ventilation backup from a vulnerability into a compliance asset, significantly reducing regulatory risk and potential penalty costs.

4. OPEX Savings: The Silent Revenue Generator (Beyond Emergency Duty):

- Peak Shaving / Demand Charge Reduction: As highlighted in Part 4, BESS intelligently discharges during peak grid demand periods.

- Typical Savings: 15-30%+ reduction in monthly demand charges.

- Annual Value: 100,000−500,000+ for large mines depending on tariff structure and load profile. (FERC – Demand Charge Impact on Industrial Users)

- Reduced Diesel Backup Reliance:

- Fuel Savings: BESS handles short outages (<30-60 mins), eliminating unnecessary diesel genset starts. Saves 500−2,000+ per avoided hour of runtime (fuel + wear).

- Maintenance Savings: Fewer genset hours = 10-20%+ reduced annual maintenance costs.

- Emissions Reduction: Avoids ~0.8 – 1.0 tons of CO₂ per avoided MWh of diesel generation, aiding ESG goals and potentially avoiding carbon costs. (EPA Emissions Factors for Stationary Diesel)

5. Peace of Mind: The Intangible (But Very Real) ROI:

- Miners: Work knowing critical life support won’t fail them. Morale and focus improve.

- Supervisors & Managers: Sleep without the dread of a 3 AM “ventilation failure” call. Reduced stress, better decision-making.

- Executives & Investors: Confidence in operational resilience and risk mitigation. Protects share value and insurability. Mines with robust safety tech like BESS often see 5-15% lower liability insurance premiums (Lloyd’s of London – Mining Risk Trends 2025).

- Community & Regulators: Enhanced reputation as a safety leader, strengthening social license to operate.

Why Maxbo Solar is Your BESS Container Powerhouse (Let’s Talk Shop)

So, you need rock-solid (pun fully intended), fail-safe BESS Container Mining Ventilation backup that won’t flinch when the grid does? That’s where Maxbo Solar comes in. We eat, sleep, and breathe robust energy storage solutions engineered for environments where failure isn’t an option.

Our Expertise: Built for Your Battlefield

At Maxbo Solar, we don’t dabble in generic storage. We specialize in designing and manufacturing industrial-grade BESS containers specifically engineered for the harsh, non-negotiable demands of mine safety and uptime in 2025. We understand that your ventilation system isn’t just equipment; it’s the lifeline for everyone underground.

Key Differentiators: Why Miners Choose Maxbo Solar

| Feature | Maxbo Solar Advantage | Industry Standard/Alternative | Why It Matters to You |

|---|---|---|---|

| Mining-First Design | Purpose-built for ventilation duty cycles: Optimized for high starting torque fan motors & continuous critical load. No repurposed telecom/data center units. | Often adapted from less demanding applications, risking undersizing or mismatched performance. | Ensures reliable performance when seconds count. Avoids compatibility failures during critical transitions. |

| Proven Ruggedness | IP66 Enclosures: Exceeds typical mining dust/water ingress challenges. -30°C to +60°C Operation: Certified for extreme portal-to-deep-mine temps. LiFePO4 Batteries: Inherently safer chemistry (thermal runaway >500°C vs. ~200°C for NMC), longer lifespan (10,000+ cycles @ 80% DoD), stable under vibration. (UL 9540A Safety Standard) |

IP54/IP55 common. Narrower temp ranges. Frequent use of higher-risk NMC chemistry. | Survives the “Oh Crap” environment. Eliminates battery fire risks. Reduces replacement costs (15+ year design life). |

| Seamless Integration | <20ms Transfer Time: True zero-interruption backup via advanced static switches. Native Compatibility: Works with all major ventilation control systems (ABB, Siemens, Eaton) & SCADA protocols (Modbus TCP, DNP3). Black Start Ready: Certified to initiate sequenced restarts. (IEEE 1547-2023) |

Slower transfer (>100ms) risks motor stalling. Custom interfaces add cost/complexity. Often lacks black start. | Guarantees fans never stop spinning. Simplifies deployment & future upgrades. Speeds full mine recovery. |

| Global Support | 24/7/365 Remote Monitoring & Diagnostics: Real-time system health & proactive alerts. Mine-Savvy Field Engineers: Average onsite response < 72hrs globally. Spare Parts Guarantee: Critical components stocked at regional hubs. (Frost & Sullivan – Global Mining Service Benchmark 2025) |

Limited business-hour support. Generic technicians. Long lead times for parts. | Minimizes downtime. Expertise you can trust when lives and production depend on it. Truly global peace of mind. |

Stop Gambling With Ventilation Backup.

Let’s discuss how Maxbo Solar’s purpose-built BESS Container solutions can transform your mine’s safety, resilience, and bottom line. Because fresh air underground shouldn’t depend on the grid’s mood.

Ready to Breathe Easier? Explore our mining-specific solutions: www.maxbo-solar.com