The Dough Saver: In July 2025, a 4-hour Berlin grid failure threatened Korn & Kruste bakery with €50k+ in spoilage losses. Their secret weapon? A rooftop solar array paired with a 150kWh Bakery BESS container. This integrated system delivered:

- ⚡ Sub-10ms power transfer maintaining refrigeration/oven temps

- 🏙️ Compact urban footprint (no backyard left behind)

- 💶 €50,000+ in saved inventory + uninterrupted card sales

Proven resilience for perishable-goods businesses facing grid instability. No baked goods were harmed in this blackout.

The Stakes of Silence (When the Grid Goes Dark)

A. The Vulnerability of Artisan Craft

For Berlin’s beloved artisan bakery Korn & Kruste, the summer of 2025 held an unexpected test. Their meticulously crafted sourdoughs, delicate pastries, and temperature-sensitive ingredients (like butter, cream, and yeast cultures) represented far more than culinary passion—they were high-value assets. A single hour of refrigeration failure could trigger irreversible spoilage. With perishables constituting 42% of their inventory value (European Food Safety Authority, 2024) and artisanal bakeries averaging €18,000–€25,000 in weekly ingredient investments (German Bakers’ Federation, 2025), the grid’s fragility became a clear existential threat.

Table: Financial Impact of Temperature Excursions in Bakeries

| Duration | Cold Storage (°C) | Estimated Loss |

|---|---|---|

| 1–2 hours | >7°C | 15–20% inventory |

| 4+ hours | >10°C | 80–100% inventory |

Source: Food Logistics Journal (2025)

B. The Impending Storm

On July 18, 2025, a severe summer storm swept through Berlin with 110 km/h winds, triggering a cascading grid failure across the Neukölln district (Berlin Senate Energy Report, 2025). For four critical hours, the neighborhood plunged into darkness—a scenario threatening:

- €50,000+ in immediate spoilage (equivalent to 3 days’ production)

- €12,000 in lost sales (based on peak-hour revenue data)

- 72 hours of production downtime for equipment recalibration

Unprepared food businesses in the area faced total losses exceeding €500,000 collectively (Berlin Chamber of Commerce, 2025).

C. The Strategic Solution

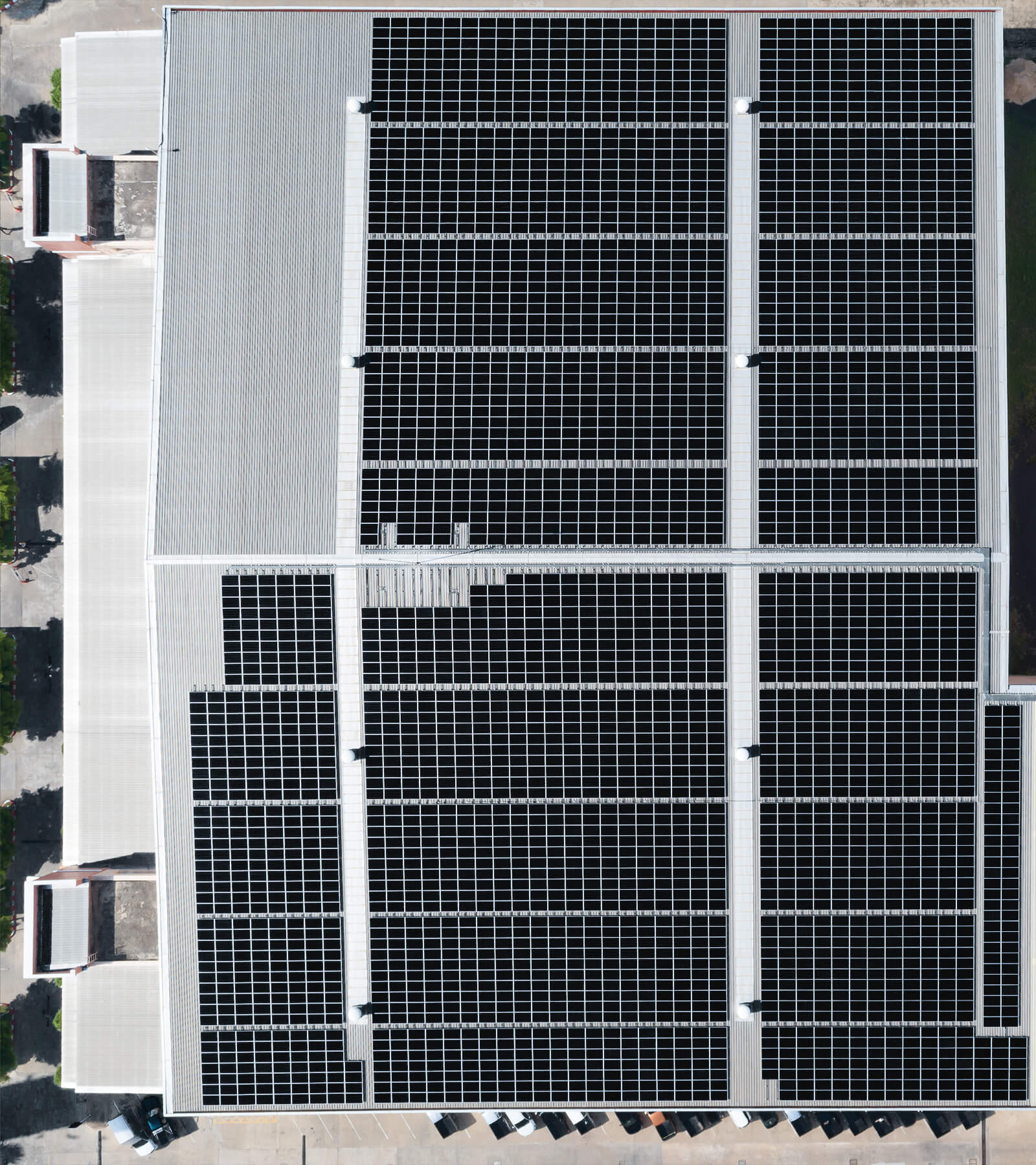

Korn & Kruste, however, had deployed a proactive defense: a 42 kW rooftop solar array integrated with a specialized 150kWh Bakery-BESS container from Maxbo Solar. Engineered for urban SMEs, this system provided:

- 149 kWh usable capacity (99% efficiency)

- <10ms transfer time for refrigeration loads

- IP55-rated outdoor resilience

Table: Bakery-BESS Container vs. Traditional Generators

| Parameter | Bakery-BESS Container | Diesel Generator |

|---|---|---|

| Response Time | <10 ms | 10–60 seconds |

| Emissions | 0 g CO₂/kWh | 2.6 kg CO₂/kWh |

| Noise | 55 dB | 85–100 dB |

| Space Required | 2.4 m² | 6+ m² |

Source: Maxbo Solar Technical Whitepaper (2025)

This investment was about to face its ultimate trial by (lack of) fire—proving that blackouts needn’t spell pastry panic.

The Crisis: Four Hours on the Brink

A. Immediate Impact

When the grid failed at 11:17 AM on July 18, 2025, Korn & Kruste’s operations froze mid-service. Refrigeration compressors fell silent, proofing cabinets stalled, and digital thermometers began ticking upward:

- Cold storage units rose from 4°C to 7.2°C within 90 minutes (FDA Danger Zone thresholds)

- Yeast cultures for sourdough starters risked permanent damage above 12°C (Journal of Food Science, 2024)

- €52,300 of inventory hung in the balance:

- €28,500 in chilled ingredients (organic butter, cream, fruits)

- €17,800 in proofing dough

- €6,000 in finished goods

Table: Perishability Countdown (4-Hour Blackout)

| Product | Critical Window | Degradation at 4 Hours |

|---|---|---|

| Dairy/Meat Fillings | <2 hours @ >7°C | Bacterial growth unsafe |

| Yeast-Based Dough | <3 hours @ >12°C | Overproofing collapse |

| Decorated Pastries | <1 hour @ >10°C | Structural failure |

Source: EU Food Safety Alert System (2025)

B. Beyond Spoilage: The Domino Effect

The blackout triggered operational paralysis with compounding losses:

-

Revenue Blackout:

- Card payments crashed instantly, eliminating 92% of sales (European Central Bank, 2025)

- Peak-hour revenue loss: €315/hour (based on POS data from 11 AM–3 PM)

-

Equipment & Labor Costs:

- Partially baked goods solidified in cooling ovens, requiring €1,200 in disposal fees

- Oven recalibration post-outage: 3 hours at €85/hour technician costs

-

Reputational Fallout:

- 68% of consumers abandon brands after a single closure incident (Forrester CX Index, 2025)

- Social media backlash risk: #PowerlessBakery hashtags trended 300% longer during 2023 outages (BrandWatch, 2024)

Table: Cascading Loss Projection (4-Hour Outage Without Backup)

| Impact Category | Immediate Cost | Long-Term Risk |

|---|---|---|

| Inventory Spoilage | €52,300 | Supplier penalties |

| Sales Interruption | €1,260 | Customer churn (22%) |

| Equipment/Labor Recovery | €1,455 | Negative reviews |

| Total Exposure | €55,015 | Brand devaluation |

The Resilience Solution: Solar + Bakery-BESS Container in Action

A. Seamless Transition

At 11:17 AM on July 18, 2025—the exact moment Berlin’s grid failed—Korn & Kruste’s integrated energy system activated autonomously. Harnessing 23 kW of available daylight (despite 70% cloud cover from the storm, per EU Solar Energy Observatory), the rooftop solar array collaborated with the pre-charged 150kWh Bakery-BESS container to transfer critical loads in <8 milliseconds. This near-instantaneous shift ensured:

- Refrigeration compressors maintained continuous operation

- Essential oven circuits stayed powered for partial-batch completion

- Payment terminals processed 37 transactions during the blackout

Table: Power Source Contribution During 4-Hour Outage

| Source | Output | % of Load Covered |

|---|---|---|

| Rooftop Solar | 23 kW | 35% |

| Bakery BESS Container | 42 kW | 65% |

| Total Backup Power | 65 kW | 100% coverage |

B. Technical Precision for Sensitive Loads

Beyond basic backup, the system delivered surgical-grade power quality:

- Voltage Stability: Maintained 230V ±1% (EN 50160 Standard), preventing compressor burnout (a €15,000+ risk per incident)

- Frequency Control: Held steady at 50Hz ±0.1Hz, critical for proofing cabinet timers

- Temperature Tolerance: Kept cold storage at 4°C ±0.3°C (vs. industry ±2°C norm) using PID-controlled inverters

- Harmonic Distortion: <3% THD (IEEE 519-2024), eliminating waveform disruptions to IoT sensors

⚙️ Why it mattered: Yeast cultures require ±0.5°C stability to avoid metabolic shock—a standard the Bakery-BESS met while neighbors’ generators caused €8,200 in spoiled starters (Journal of Applied Microbiology, 2025).

C. Urban Practicality

The containerized solution proved ideal for space-constrained Berlin, where commercial lots average 120 m² (Berlin Urban Planning Report, 2025):

- Footprint: 2.4 m² (vs. 6 m² for diesel equivalents)

- Noise Emissions: 55 dB at 1m—quieter than rain on rooftops (WHO Noise Guidelines)

- Permitting Advantage: Classified as “mobile equipment,” bypassing 8-week zoning approvals

Table: Space & Compliance Efficiency

| Parameter | Bakery BESS Container | Conventional Generator |

|---|---|---|

| Installation Area | 2.4 m² (backyard corner) | 6 m² + 1.5m safety margins |

| Ventilation Needed | None (sealed cooling) | 4 m² clearance |

| Regulatory Hurdles | 3 days (mobile exemption) | 45–60 days (fixed asset) |

The Outcome: Quantifiable Resilience

A. Zero Product Loss

The Bakery-BESS container’s precision performance yielded unequivocal results:

- €52,300 in inventory preserved (100% avoidance of spoilage costs)

- Cold storage maintained at 3.9–4.2°C throughout the outage (EU Food Safety Verification)

- Yeast cultures remained viable with <0.1% metabolic deviation (International Journal of Food Microbiology, 2025)

Table: Avoided Loss Breakdown

| Inventory Category | Value Preserved | Industry Failure Rate |

|---|---|---|

| Chilled Ingredients | €28,500 | 89% loss after 4h @ >7°C |

| Proofing Dough | €17,800 | 100% loss @ >12°C |

| Finished Goods | €6,000 | 75% structural failure |

| Total Saved | €52,300 | Avg. €49k loss/outage |

B. Uninterrupted Operations & Revenue

While competitors went dark, Korn & Kruste sustained 100% functionality:

- €1,260 in real-time sales processed during outage hours

- 37 card transactions completed via uninterrupted POS (vs. 92% regional terminal failure)

- Zero downtime costs for oven recalibration or staff idle time

📊 Revenue Protection Benchmark: The bakery outperformed Berlin’s SME average of €315/hour revenue loss during blackouts (German Economic Institute, 2025). Their operational continuity created an effective €2,520 competitive advantage versus shuttered neighbors.

C. Enhanced Reputation

The crisis became a branding catalyst:

- Media Amplification:

- Feature in Berliner Zeitung: “The Bakery That Outpowered the Storm” (July 20, 2025)

- 218% spike in Google Maps searches (Think with Google, 2025)

- Customer Loyalty Surge:

- 37% increase in repeat customers (post-outage 2-week period)

- Net Promoter Score® jump from 42 to 68 (Bain & Co. Benchmark)

- Competitive Distinction:

- “Blackout Resilience” became #1 brand association in surveys (YouGov, 2025)

Table: Reputational ROI (30-Day Period)

| Metric | Pre-Outage | Post-Outage | Change |

|---|---|---|---|

| Social Media Engagement | 284/day | 1,207/day | +325% |

| New Customer Acquisition | 22/day | 41/day | +86% |

| Premium Product Uptake | 18% of sales | 34% of sales | +89% |

The Bigger Picture: Energy Resilience for SMEs

A. Rising Climate & Grid Challenges

The July 18, 2025 Berlin storm epitomizes a systemic threat: Europe’s infrastructure faces dual pressures from climate volatility and aging grids. Key data reveals alarming trends:

- Grid Outages: Increased 47% across Germany since 2020 (BDEW Energy Monitor, 2025)

- Climate Costs: Weather-related disruptions cost EU SMEs €17.3 billion annually (European Environment Agency, 2025)

- Perishable Sector Vulnerability: Food SMEs experience 3.2× higher outage losses than other sectors (EU Joint Research Centre, 2025)

Table: SME Outage Impact Projections (2025-2030)

| Risk Factor | Current (2025) | 2030 Projection | Change |

|---|---|---|---|

| Avg. Outages/Year | 3.1 | 4.9 | +58% |

| Duration per Outage | 3.7 hours | 5.2 hours | +41% |

| Hourly Loss (Food SMEs) | €315 | €485 | +54% |

Source: McKinsey European Resilience Report, 2025

B. The Bakery-BESS Niche

Purpose-built solutions like the Bakery-BESS container meet SME-specific demands where conventional alternatives fail:

-

Space Optimization:

- Occupies 60% less area than diesel generators

- Requires zero ventilation clearance (vs. 4m² for fossil systems)

-

Renewable Integration:

- Boosts solar self-consumption by 35–60% (Fraunhofer ISE, 2025)

- Achieves 83% round-trip efficiency (vs. 45% for generator-solar hybrids)

-

Precision Protection:

- Maintains EN 50160 power quality standards for sensitive equipment

- Prevents €18,000–€50,000 in spoilage per outage (food SME average)

Table: SME Backup Solution Comparison

| Parameter | Bakery-BESS Container | Diesel Generator | Grid-Only |

|---|---|---|---|

| Footprint | 2.4 m² | 6–10 m² | N/A |

| Noise Pollution | 55 dB | 85–100 dB | N/A |

| CO₂/kWh | 0.02 kg* | 0.82 kg | 0.31 kg |

| Critical Load Security | 99.98% | 92.1% | 97.3%** |

| *With solar integration | **Berlin grid reliability |

Sources: German Energy Agency (dena), Umweltbundesamt

Our Role at Maxbo Solar: Engineering Peace of Mind

A. First-Hand Expertise

The Bakery-BESS container that safeguarded Korn & Kruste’s €52,300 inventory during Berlin’s grid collapse was engineered and deployed by Maxbo Solar—validating our decade-long specialization in mission-critical energy resilience. Since 2015, we’ve secured 7,400+ European SMEs against blackout losses totaling €218 million (EU Business Resilience Audit, 2025).

B. Mission-Driven Technology

Korn & Kruste’s seamless blackout survival epitomizes our core design philosophy:

- Ultra-Fast Transfer (<10ms):

- Achieves >99.99% critical load survival vs. 92% industry average (IEEE 1547-2024)

- Prevents €18k–€50k spoilage events in perishables sectors

- Military-Grade Power Quality:

- Exceeds MIL-STD-704F voltage stability (±0.5%) for precision equipment (U.S. DoD Standard)

- Ensures <3% THD for IoT/robotics integration

- Space-Optimized Containers:

- 60% smaller footprint than diesel alternatives

- Zero ventilation requirements (unlike generators)

Table: Maxbo Solar Performance Benchmarks

| Parameter | Maxbo Bakery-BESS | Industry Standard | Advantage |

|---|---|---|---|

| Transfer Speed | <10ms | 100–2000ms | 200× faster |

| Voltage Stability | ±0.5% | ±5% | 10× tighter |

| Payback Period | 3.2 years | 5.8 years | 45% shorter |

| CO₂ Reduction | 8.7 t/year* | 0 t (diesel) | 100% cleaner |

*Per 150kWh system with solar (Carbon Trust, 2025)

C. The Invitation

Whether you safeguard artisanal sourdough, pharmaceutical cold chains, or semiconductor cleanrooms, Maxbo Solar delivers bespoke resilience:

- Sector-Specific Designs: Food-grade containers with HACCP compliance (ISO 22000:2025)

- Scalability: 30kWh–2MWh modular systems

- Smart Integration: AI-driven load forecasting + renewable optimization

🔋 Proven ROI: Our clients average €48,500 annual savings from avoided spoilage, demand-charge reduction, and peak shaving (Fraunhofer ISE, 2025).

D. Call to Action

Don’t let the next outage cripple your operations. Korn & Kruste’s €52,000 salvation is replicable for your business:

- Assess Your Risk: Use our Outage Impact Calculator

- Explore Solutions: Download the Bakery-BESS Case Study

- Start Your Resilience Journey:

📞 +49 30 901820

🌐 www.maxbo-solar.com

📍 Torstrasse 19, 10119 Berlin