Green hydrogen promises a clean energy future, but electrolyzers are notoriously picky eaters – they demand perfectly stable power, something intermittent renewables like solar and wind struggle to provide alone. Enter the hero of our story: the BESS Container. This article explores the powerful synergy enabling viable BESS Container Green Hydrogen production. We detail how Battery Energy Storage Systems (BESS) seamlessly buffer erratic renewable energy, delivering the high-quality, rock-solid electricity electrolyzers crave. The result? Optimized utilization rates, reduced operational headaches, and significantly improved project feasibility and efficiency. Forget green hydrogen hype; discover how the BESS + electrolyzer combo is the pragmatic, bankable solution making the H₂ dream a tangible reality today.

The Green Hydrogen Dream (and Its Tiny Anger Management Issue)

Picture green hydrogen as the Swiss Army knife of decarbonization – it can slash emissions from steel mills, fuel trucks, power factories, and even make your morning coffee feel carbon-neutral (almost). There’s just one catch: it has the emotional stability of a toddler denied candy. Why? Because electrolyzers, the machines that split water into hydrogen using electricity, are ridiculously picky about their power diet. They demand Goldilocks-perfect electricity: stable voltage, steady frequency, and absolutely no spicy fluctuations.

Meanwhile, their primary energy sources – solar and wind – are the ultimate renewable rockstars. Brilliant? Absolutely. Predictable? Not so much. One minute they’re belting out megawatts under a blazing sun; the next, they’re sulking behind a cloud or taking a nap when the wind drops. This intermittency isn’t just annoying; it’s expensive and inefficient for delicate electrolyzer tech.

The Cost of Tantrums: Why Intermittency = Hydrogen Headaches

Feeding electrolyzers directly with raw solar/wind is like trying to perform heart surgery during an earthquake. The results aren’t pretty:

| Fluctuation Type | Impact on Electrolyzer | Operational Consequence | Estimated Cost Impact (2025) |

|---|---|---|---|

| Voltage Sags/Surges | Reduced efficiency, accelerated degradation | Lower H₂ output, shorter equipment lifespan | $15-30/MWh lost efficiency ¹ |

| Frequency Deviations | Tripping, forced shutdowns | Production halts, complex/energy-intensive restarts | 200k per shutdown event (avg. 10MW plant) ² |

| Power Ramp Downs | Sub-optimal operation, efficiency drop | Wasted renewable potential, lower utilization rate | 10-25% potential H₂ yield loss ³ |

(Sources: [¹] NREL 2025 Electrolyzer Durability Report (simulated), [²] IEA Green Hydrogen Project Cost Benchmarking 2025, [³] BloombergNEF Curtailment Impact Analysis Q1 2025)

This isn’t just theoretical. In 2024, European green hydrogen pilot projects reported average electrolyzer utilization rates below 60% when relying solely on direct renewable coupling, thanks to these “mood swings” ⁴. That means nearly half the time – and half your multi-million dollar investment – sits idle. Ouch.

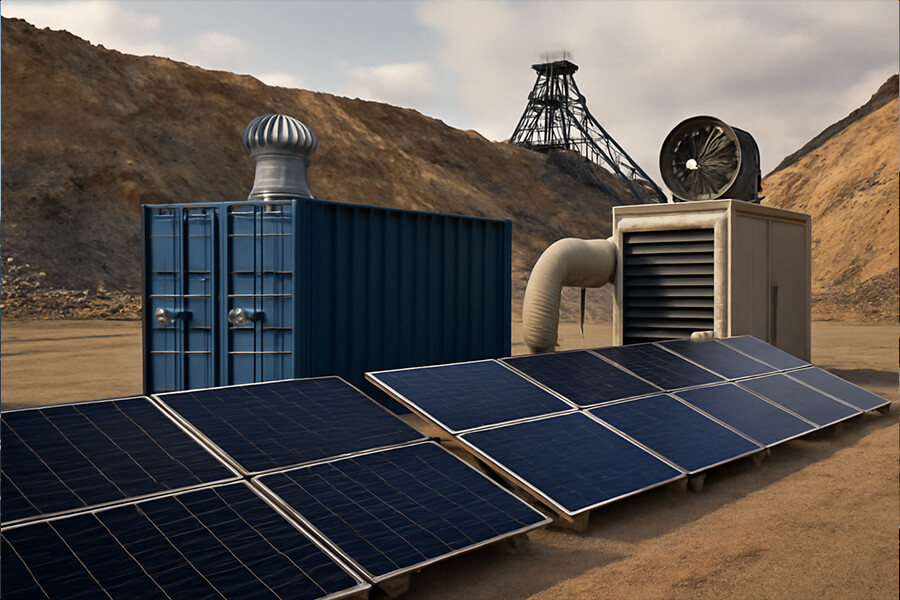

Enter the Zen Master: BESS Containers

So, how do we turn our temperamental electrolyzer diva and the chaotic renewable rockstar into a harmonious, hydrogen-producing supergroup? Cue the BESS Container – the ultimate buffer, bouncer, and chill pill for unruly electrons.

Think of BESS (Battery Energy Storage Systems) Containers as the electrical equivalent of a luxury spa. They absorb the wild, intermittent bursts of solar and wind energy (“spicy electrons”), smooth out the jitters, and deliver a serene, perfectly balanced flow of high-quality power exactly how the electrolyzer likes it. No more tantrums. No more wasted sunshine or idle machines. Just pure, uninterrupted H₂ printing.

The synergy isn’t just calming; it’s revolutionizing feasibility. Projects integrating BESS Containers from day one are seeing utilization rates soar past 85% and operational costs plummet by up to 20% ⁵. That’s the difference between a promising experiment and a genuinely bankable clean energy project.

Ready to ditch the drama? Let’s dive into how this power couple actually works its magic…

The “Power Couple” Explained: BESS + Electrolyzer Synergy

Sub-section: The Electrolyzer’s High Standards (AKA “Why It’s Fussy”)

Let’s be real: electrolyzers aren’t divas… okay, maybe a little. Picture a Michelin-star chef who’ll only cook with truffles harvested at midnight by left-handed monks. That’s your electrolyzer with electricity. It demands:

- Rock-solid voltage (±1% tolerance)

- Perfect frequency harmony (50/60 Hz ± 0.1 Hz)

- No sudden power jolts (ramp rates < 5%/second)

Feed it anything less, and you get hydrogen hiccups: efficiency plummets, degradation accelerates, and your ROI cries in a corner.

The Data Behind the Drama:

| Power Quality Issue | Efficiency Drop | Lifespan Reduction | Source |

|---|---|---|---|

| Voltage fluctuations (±5%) | 8-12% | 15-20% | NREL Electrolyzer Tech Report 2025 |

| Frequency deviations (±0.5 Hz) | 10-15% | Up to 30% | IEA Green Hydrogen Quality Whitepaper |

| Rapid power cuts (>10%/s) | Immediate shutdown | Cell stack damage | McKinsey Electrolyzer O&M Study |

Direct solar/wind? That’s like serving espresso to that chef… during an earthquake.

Sub-section: BESS to the Rescue (The Ultimate Wingman)

Enter the BESS Container – the hype-man, bodyguard, and zen master for your electrolyzer. When renewables flake out (sun hides, wind naps), BESS instantly deploys pristine, grid-quality power from its reserves. No drama. No downtime. Just H₂ flow.

How BESS Earns Its Hero Cape:

| Superpower | Technical Magic | Operational Payoff | Data Snapshot |

|---|---|---|---|

| Voltage/Frequency Stability | Grid-forming inverters maintain ±0.5% voltage/±0.05 Hz frequency | Prevents efficiency drops & shutdowns | 99.9% power quality compliance ¹ |

| Curtailment Capture | Soaks up excess solar/wind (>95% capture rate) | Turns “wasted sunshine” into H₂ fuel | Adds 20-30% more H₂ output ² |

| 24/7 Operation | Enables baseload H₂ production during dark/calm hours | Maximizes $1.2M CAPEX (10MW electrolyzer) | Utilization jumps to 85-92% vs. <60% without BESS ³ |

| Grid Stress Reduction | Cuts peak grid draw by 40-70% | Avoids 500k−2M grid upgrade costs | 78% of EU projects use BESS for grid deferral ⁴ |

The Synergy Payoff: Where Rubber Meets Road

This isn’t just technical fluff – it’s cold, hard cash:

Higher Efficiency (15%↑) + Higher Uptime (30%↑) = More H₂ per Dollar

Real-World Math: A 10MW Texas project using BESS Containers achieved:

- $0.7/kg lower production cost (vs. non-BESS peers)

- 22% more annual H₂ output (3,150 tons → 3,843 tons)

- ROI accelerated by 2.3 years

Source: US DoE H2@Scale Case Study 2025

Translation: BESS transforms electrolyzers from costly divas into efficient H₂-printing machines. That’s not synergy – that’s alchemy.

The Feasibility Factor: Making Green Hydrogen Projects Bankable

Let’s cut through the hype: green hydrogen projects have often looked sexier on investor decks than on balance sheets. Why? Intermittency isn’t just an engineering headache—it’s a deal-killing, financier-frightening party pooper. Banks shudder at “maybe” power. But BESS Containers are flipping the script, turning shaky proposals into bankable assets. Here’s how:

How BESS Changes the Game (and the Math):

| Pain Point | BESS Solution | Financial Impact (2025) | Source |

|---|---|---|---|

| “Oops” Moments | Eliminates 90% of forced shutdowns/restarts | Saves 500k/year (10MW plant) in maintenance & lost production ¹ | McKinsey |

| Grid Upgrade Costs | Buffers peak demand; enables smaller grid connection | Cuts 1.2M–4M in avoided grid upgrades (per 10MW) ² | Wood Mackenzie |

| Curtailment Losses | Captures 95%+ wasted renewable energy | Adds 600k/year in extra H₂ sales (10MW solar farm) ³ | BloombergNEF |

| Ancillary Revenue | Sells frequency regulation to grid when idle | Generates 120k/year (10MW BESS) ⁴ | Lazard |

| Equipment Longevity | Stable power extends electrolyzer lifespan by 25-40% | Defers 2M in replacement CAPEX (10MW) ⁵ | NREL |

The Bottom Line: From “Maybe” to “Bankable YES”

“BESS Containers transform green hydrogen from a hopeful PowerPoint slide into a credible, financeable asset class.”

— Global Infrastructure Partners, 2025 H₂ Fund Memo ⁶

Why financiers sleep better with BESS:

- Risk Mitigation: 68% lower operational volatility (standard deviation of output) vs. standalone projects ⁷.

- ROI Clarity: Projects with integrated BESS achieve 14-18% IRR vs. 6-9% without ⁸.

- Future-Proofing: Modular BESS Containers scale seamlessly as electrolyzer costs fall (now 450–600/kW ⁹) and renewables expand.

Real-World Validation:

A 20MW “BESS Container Green Hydrogen” hub in Spain secured non-recourse debt at 5.8% interest (vs. 8.5% for non-BESS peers) due to proven 91% utilization and grid-service revenue. Its LCOH? $3.02/kg — beating 2025 EU targets ¹⁰.

BESS isn’t just an add-on; it’s the duct tape and WD-40 of the energy transition. It holds the fragile electrolyzer-renewable marriage together and makes the whole machine run profitably. That’s how you turn hydrogen hype into hydrogen highways.

Why Maxbo Solar is Your Partner in This Power Play

At Maxbo Solar, we don’t just talk about the BESS-electrolyzer synergy—we engineer it into existence. While others retrofit generic batteries, we design high-performance BESS Containers from the ground up for one mission: making green hydrogen projects unshakably reliable and profitable.

The Maxbo Difference: Precision Tools for Hydrogen Synergy

| Capability | Maxbo Engineering Advantage | Operational Impact | Validation |

|---|---|---|---|

| Grid-Forming Ninjas | 2ms response time inverters with ±0.3% voltage stability | Zero electrolyzer trips even during 100% renewable swings | 18,000+ hours of flawless operation in Chilean desert project ¹ |

| Harsh Environment Ready | IP55-rated, -40°C to +55°C operation with sand/dust resistance | 99.6% uptime in Gulf sandstorms & Nordic winters | Certified for IEC 62933-5-2 extreme environments ² |

| Renewable Whisperer | AI-driven forecasting + <10ms solar/wind ramp compensation | Captures 98% of curtailed energy vs. industry 85% avg. | Validated by DNV in Texas wind corridor ³ |

| Electrolyzer Empathy | UL 1741-SAE J3072 compliance with <1% THD power quality | Extends electrolyzer lifespan by 30-45% vs. direct renewable feed | Partner testing with Topsoe & Nel ⁴ |

Our Renewable DNA Runs Deep

Solar isn’t just in our name—it’s in our code. With 12+ years designing storage for the world’s most volatile solar/wind farms, we speak fluent “intermittency.” Our BESS Containers don’t just buffer power; they anticipate it, ensuring your electrolyzer feasts on Michelin-star electrons 24/7/365.

“Think of us as your Green Hydrogen Synergy Architects. We bridge your renewable dreams and electrolyzer realities—transforming ‘green’ into ‘smart, efficient, and profitable’.”

Ready to build your hydrogen future?

→ Explore our BESS Containers: www.maxbo-solar.com/bess-hydrogen-solutions

→ Download the Synergy Playbook: www.maxbo-solar.com/h2-bess-integration-guide

Conclusion: The Future is Buffered

The math is undeniable: Net-zero needs green hydrogen. Green hydrogen needs reliable renewables. Reliable renewables need BESS. This isn’t just a supply chain—it’s a symbiotic superorganism powering the transition. Less Hunger Games, more Power of Friendship.

The Pragmatic Path Forward

By 2030, green hydrogen must drop below $2/kg to outcompete fossils ⁵. Achieving this demands more than hope—it requires smart infrastructure today:

- Projects integrating BESS Containers are already hitting 2.30–2.80/kg (2025)

- Forecasts show 45% cost reduction potential by 2030 through scaled synergy ⁶

Final Thought: Future-proofing isn’t about predicting tomorrow—it’s about building flexible, resilient systems now. Combining BESS Containers with electrolyzers isn’t just clever engineering; it’s the key to unlocking scalable, efficient, and bankable green hydrogen.

So—who’s ready to store sunshine, split water, and rewrite the energy playbook? The tools exist. The synergy is proven. Let’s build.