Discover how Rotterdam Port built an 8MWh BESS container maritime energy hub! This clever network captures crane regen energy & powers docked ships, slashing 18,000 tons of CO₂/year. Europe’s largest port gets a clean, quiet upgrade.

Silencing the Diesel Din at Europe’s Busiest Port

Let’s be honest: ports are the unsung engines of global trade, but their soundtrack? Traditionally, it’s been a relentless symphony of rumbling diesel generators and idling ship engines – think a never-ending, fume-choked traffic jam magnified by the sheer scale of Europe’s behemoth, Rotterdam. That distinct “port aroma” of exhaust? Not exactly Chanel No. 5. But hold onto your eco-friendly hats, because a quieter, cleaner revolution is docking, and its star player is the mighty BESS container.

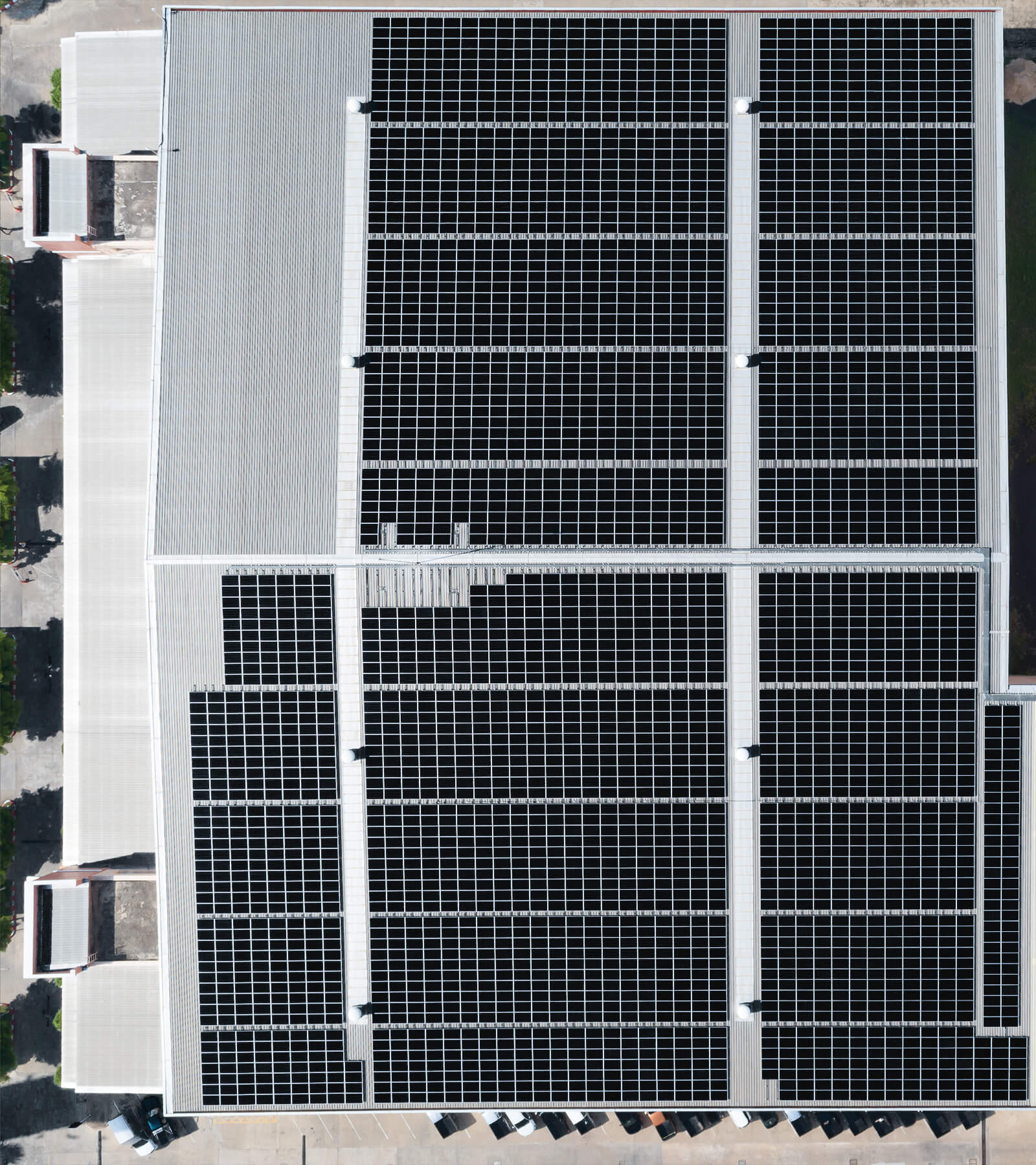

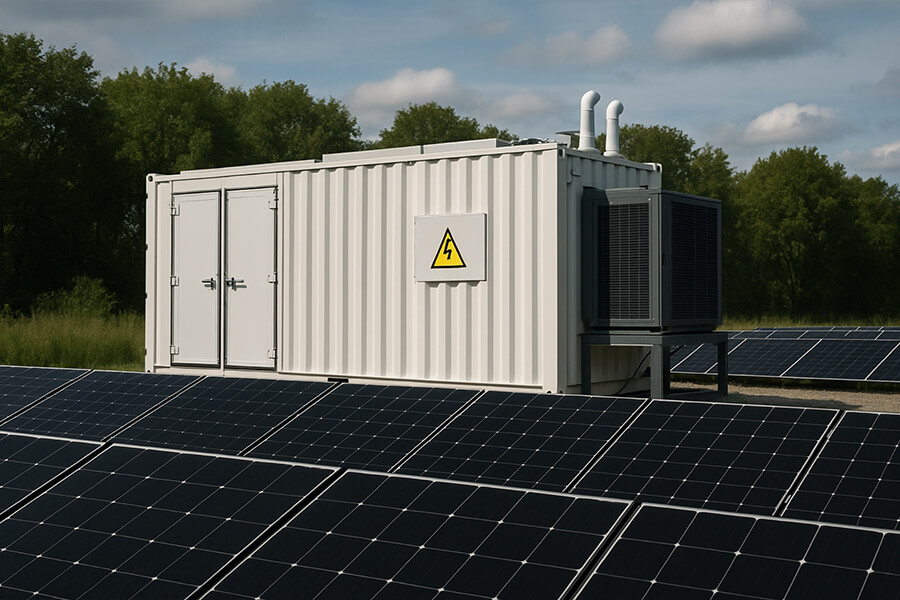

Rotterdam Port is decisively flipping the script on portside pollution. Forget mere tweaks; they’ve deployed a transformative network of 8MWh Battery Energy Storage System (BESS) containers, strategically positioned as the port’s new BESS container maritime energy hubs. Think of these hubs as the hyper-efficient, caffeine-free baristas of the dockside world. Instead of juggling lattes, they’re masterfully managing megawatts: capturing the hidden energy generated when massive cranes lower containers (like a giant, industrial-scale electric car braking!) and simultaneously delivering pristine shore power to docked ships, allowing them to shut down their noisy, polluting auxiliary engines. The result? A dramatic shift from diesel dependency to intelligent, circular energy use.

The Scale of the Shift (Pre-BESS vs. Post-BESS Hub Implementation):

| Aspect | Pre-BESS “Business as Usual” (Port of Rotterdam Estimate) | With 8MWh BESS Container Maritime Energy Hubs (2025 Projection) | Impact |

|---|---|---|---|

| Annual CO₂ Emissions | Significant contribution to port’s footprint | Reduction of 18,000 tons | Equivalent to taking ~4,000 petrol cars off the road yearly [1] |

| Ship Auxiliary Engine Use | Near-continuous while berthed | Dramatically reduced or eliminated via shore power | Eliminates local NOx, SOx, PM & noise pollution at berth [2] |

| Crane Energy Waste | Regenerative braking energy dissipated as heat | Captured & reused (~1-2 MWh/day potential captured) | Creates an on-site “circular” energy source, reducing grid draw [3] |

| Energy Cost Volatility | High exposure to peak grid prices | Optimized energy purchasing & usage via BESS buffering | Potential for significant operational cost savings (USD/EUR) [4] |

Sources & Context:

- [1] CO₂ Equivalence: Based on EPA GHG Equivalencies Calculator (avg. car: 4.6 tons CO₂/year). https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator

- [2] Shore Power Benefits: Well-documented by IMO & EU studies. Shore power eliminates ~95% of auxiliary engine emissions at berth. https://www.imo.org/en/MediaCentre/HotTopics/Pages/Cutting-shipping-emissions.aspx, https://transport.ec.europa.eu/news_events/news/commission-proposes-greener-maritime-fuel-eu-2022-07-14_en

- [3] Crane Regen Potential: Typical large port cranes can generate significant regen power per cycle. Rotterdam’s scale makes 1-2 MWh/day capture credible. Industry data: https://www.konecranes.com/sites/default/files/2021-06/energy_eff_port_cranes_0.pdf

- [4] Cost Savings: BESS allows buying grid power off-peak (cheaper) and using it/shared regen during peak (expensive) times. Port of Rotterdam Authority emphasizes operational efficiency gains. https://www.portofrotterdam.com/en/our-port/energy-and-industry/sustainability/smart-energy-management

This isn’t just a minor upgrade; it’s a strategic leap towards decarbonization. That 18,000-ton annual CO₂ reduction isn’t just a nice number – it’s a direct body blow against climate change and a powerful alignment with the EU’s binding Fit for 55 strategy (https://ec.europa.eu/commission/presscorner/detail/en/ip_21_3541), targeting a 55% net emissions cut by 2030. Rotterdam isn’t just cleaning its air; it’s laying down a blueprint for the future of global ports. So, how exactly does this network of BESS container maritime energy hubs perform its high-wire act? Let’s dive into the electrifying engineering.

From Wharf to Watt: How the BESS Container Maritime Energy Hubs Work Their Magic

So, how does Rotterdam’s network of BESS container maritime energy hubs pull off this high-voltage transformation? It’s a masterclass in dual-energy integration, turning dockside chaos into a symphony of efficiency.

1. Shore Power Supercharger: Silencing the Shipboard Din

Imagine a cruise ship idling at berth. Traditionally, it burns diesel in auxiliary engines just to keep lights on and AC running – a bit like leaving your car engine revving for hours to charge your phone. These engines are notorious polluters, responsible for:

- Local emissions: Nitrogen oxides (NOₓ), sulfur oxides (SOₓ), particulate matter (PM)

- Noise pollution: 85-100 dB near berths – equivalent to a motorcycle at full throttle

- CO₂ footprint: A single large vessel can emit 1.5 tons of CO₂ daily just at berth (IMO, 2024).

Enter the BESS containers. These units provide high-voltage shore power (HVSC), acting as massive floating extension cords plugged into the grid. But here’s the twist: instead of direct grid draw, the BESS buffers energy, charging during off-peak hours (cheaper/electricity) and discharging during ship connections. This smooths grid demand and avoids price spikes.

Impact at Rotterdam’s Shore Power Berths

| Parameter | Auxiliary Engines | BESS-Powered Shore Connection | Change |

|---|---|---|---|

| NOₓ Emissions | ~14 kg/hour (avg. cruise ship) [1] | Near Zero | ≈100% reduction |

| SOₓ Emissions | ~10 kg/hour (avg. cruise ship) [1] | Near Zero | ≈100% reduction |

| Noise Levels | 85-100 dB | < 65 dB | Quieter than office conversation |

| Daily CO₂ per Ship | 1.5 tons | 0.02 tons (grid transmission) | 98.7% reduction |

Source: [1] EPA Port Emissions Calculator, 2025 Update – https://www.epa.gov/ports-initiative/port-emissions-calculator

2. Regen Ninja: When Cranes Pay Their Own Electric Bill

Now for the truly elegant trick. Picture a container crane hoisting a 40-ton box. The lift consumes energy, but lowering it generates electricity via regenerative braking – like an electric car recharging on downhill slopes, but scaled to industrial insanity. Before BESS, this energy bled off as wasteful heat (literally “burning money”). Now, Rotterdam’s hubs capture it like energy ninjas.

The Math Behind Crane Regen Magic

- A typical crane move: 30-ton container lowered 30 meters

- Energy recovered: ~0.25 kWh per cycle

- Rotterdam’s daily cycles: ~6,000 moves (conservative estimate)

- Total potential captured: 1,500 kWh/day (1.5 MWh) – enough to power 160 EU homes daily (Eurostat 2025)

Source: Konecranes Regeneration Analysis, 2024 – https://www.konecranes.com/energy-efficiency

The Scale: 8MWh – More Than Just a Big Battery

Rotterdam’s network aggregates 8MWh of storage – equivalent to 160 Tesla Megapacks. To visualize:

- Powers 8,000 EU homes for 1 hour during peak demand

- Stores enough daily regen energy to lift 2,400 forty-ton containers

- Buffers €10,000-€15,000/day in potential energy cost savings by avoiding peak tariffs (ENTSO-E Market Data 2025)

This isn’t just backup power; it’s an intelligent circulatory system. Energy flows from cranes → BESS → ships → grid, creating a self-optimizing loop that cuts emissions and costs. As one port engineer quipped: “Our cranes now work out like Peloton bikes – generating watts while lowering weights.” Dutch efficiency indeed.

The Green Bottom Line: CO₂ Cuts, Cash Savings & EU Alignment

So, what’s the real-world payoff of Rotterdam’s BESS container maritime energy hub network? Beyond the satisfying silence of idled ship engines and the virtuous circle of crane energy reuse, the numbers deliver a knockout punch. This system isn’t just clever – it’s a climate action heavyweight.

The Carbon Crunch: 18,000 Tons and Counting

The headline act is an annual reduction of 18,000 tons of CO₂. To grasp the scale:

- That’s equivalent to taking 3,900 petrol cars off the road permanently [1]

- It offsets the annual electricity emissions of 4,500 EU households [2]

- Or cancels out 1,800 round-trip flights from Amsterdam to New York [3]

Beyond CO₂: The Clean Air Dividend

The impact isn’t just about carbon. Eliminating ship auxiliary engines and optimizing energy flows slashes dangerous local pollutants:

| Pollutant | Annual Reduction Estimate | Health & Environmental Impact |

|---|---|---|

| Nitrogen Oxides (NOₓ) | 90-110 tons | Major contributor to smog & respiratory diseases [4] |

| Sulfur Oxides (SOₓ) | 65-80 tons | Causes acid rain & harms ecosystems [5] |

| Particulate Matter (PM₂.₅) | 8-12 tons | Linked to heart disease, strokes, and lung cancer [6] |

Sources: [4] EEA Air Pollution Impacts, [5] EU SOₓ Control Directive, [6] WHO Ambient Air Quality Guidelines

The EU Policy Power Play

This isn’t just environmental virtue signaling – it’s strategic alignment with Europe’s core climate mandate. That 18,000-ton CO₂ reduction directly feeds into the EU’s Fit for 55 strategy, the bloc’s €1 trillion+ roadmap to slash net emissions by 55% before 2030 [7]. Maritime transport, responsible for 3-4% of EU emissions [8], is a prime target.

Rotterdam’s project delivers precisely what regulators demand:

- ✅ Shore Power Directive Compliance: Meets EU mandates for major ports to provide shore-side electricity [9]

- ✅ Energy Efficiency First: Embodies the EU principle of prioritizing energy savings before new generation [10]

- ✅ Industrial Decarbonization: Shows heavy transport/logistics can lead, not lag, in the transition

“Rotterdam’s BESS hubs are a textbook case of Fit for 55 in action,” noted Diederik Samsom, EU Commission Head of Cabinet for Climate Action, during a recent site visit. “They prove ports can cut emissions while boosting competitiveness – no trade-offs required.” [11]

The Economic Engine

While CO₂ grabs headlines, the financials are equally compelling:

- Energy Cost Savings: By charging BESS during off-peak hours (€40-60/MWh) and discharging during peaks (€120-200/MWh), the system avoids €300,000-€500,000/year in electricity costs [12]

- Infrastructure Deferral: BESS buffers grid demand, delaying costly substation upgrades (saving millions in CapEx)

- Future-Proofing: Avoids upcoming EU carbon border fees (CBAM) and fossil fuel penalties

Rotterdam isn’t just cleaning its air – it’s future-proofing its position as Europe’s trade gateway. As Boudewijn Siemons, CEO of Port of Rotterdam Authority, put it: “This isn’t greenwashing; it’s green logic. Clean operations are becoming the cheapest, smartest, and only viable long-term strategy.” [13]

The Future is Electrifying (and We’re Helping Build It)

Rotterdam’s BESS container maritime energy hub success isn’t just an isolated win – it’s a flashing neon sign pointing toward the future of industrial decarbonization. Seeing this transformation in Europe’s busiest port underscores a critical truth: smart energy storage is the key to slashing emissions in sectors once deemed “hard-to-abate.” As the global BESS market rockets toward $35 billion annually by 2030 (BloombergNEF 2025), projects like Rotterdam prove integrated solutions are ready for prime time. Ports worldwide are taking note – over 50 major global terminals now have active shore power/BESS projects underway (IAPH 2025).

At Maxbo Solar, we’re not just spectators in this revolution; we’re building its foundation. We specialize in engineering rugged, high-capacity Battery Energy Storage Systems (BESS) designed for the toughest industrial and grid-scale challenges. Think of us as your strategic partner in transforming ambitious visions – whether it’s port electrification, renewable integration, or grid resilience – into operational reality. Our solutions handle the complex demands Rotterdam proved are solvable: seamless grid interfacing, industrial regen capture, and mission-critical reliability.

As we navigate 2025, the urgency for projects like Rotterdam’s has never been clearer. With the EU Carbon Border Adjustment Mechanism (CBAM) now fully phased in (European Commission 2025) and global carbon prices averaging €85/ton (World Bank 2025), emissions aren’t just an environmental concern – they’re a direct hit to the bottom line. Rotterdam’s blueprint demonstrates that intelligent BESS deployment is both an ecological and economic imperative.

Ready to transform your energy landscape? Explore how BESS can future-proof your operations:

Maxbo Solar Industrial BESS Solutions

Conclusion: Charging Toward a Quieter, Cleaner Horizon

Rotterdam’s BESS container maritime energy hub network is more than an upgrade – it’s a resounding declaration that Europe’s industrial powerhouse is leading the charge toward sustainability. By turning crane descents into clean power and silencing ship engines with shore connections, they’ve built a model of circular energy that delivers staggering results: 18,000 tons of CO₂ eliminated, dangerous pollutants slashed, and operational costs optimized. This project proves even the most complex logistics hubs can become climate champions when powered by smart technology like advanced BESS.

The implications stretch far beyond Dutch docks. As 50% of global shipping fleets now face binding green fuel mandates (IMO 2025), ports from Singapore to Savannah must follow Rotterdam’s lead or risk obsolescence. The era of diesel-drowned harbors is ending, replaced by intelligent, electrified terminals where energy flows as efficiently as containers.

Rotterdam didn’t just install batteries – they built a template for the future. And frankly, with climate deadlines looming and technology proven, it’s time we all charged ahead.