Out with the Dinosaurs, In with the Silent Powerhouse: Forget clunky, smoke-belching diesel generators. Amsterdam’s latest Tier IV data center upgrade features a game-changing BESS container mission-critical UPS solution. This liquid-cooled, 3MWh powerhouse boasts a blistering 2C-rate discharge capability – delivering full backup power in minutes, not moments after you need it. The result? A rock-solid 99.999% uptime and a jaw-dropping 60% reduction in backup costs (yes, your CFO will cheer). Certified to the stringent UL 9540A safety standard, this isn’t just backup; it’s smarter, cleaner, and significantly cheaper resilience. Diesel’s era of noise, fumes, and expensive maintenance is officially over. Discover how this Amsterdam hub traded roars for reliability.

The Not-So-Romantic Relationship with Diesel

Picture this: Amsterdam, 2025. Canals shimmer, historic architecture stands tall, tulips bloom… and then BRRRRAAAAAPPP! The guttural roar of a diesel generator shatters the calm as it lurches to life during a minor grid flicker at a Tier IV data center. For decades, that jarring sound was synonymous with resilience for mission-critical facilities. But let’s be brutally honest: relying on these diesel dinosaurs for backup power feels less like a reliable partnership and more like dealing with that one exhaustingly high-maintenance friend. Let’s break down why the romance has well and truly fizzled:

- The Insatiable Appetite (Fuel Costs): Feeding these beasts is a wallet-crushing affair. Diesel prices remain volatile, and Tier IV facilities require vast on-site fuel reserves and complex delivery logistics just to ensure readiness. Imagine budgeting for thousands of liters constantly sitting idle just in case, plus the cost of refueling and storage maintenance. Current diesel prices in the Netherlands hover around €1.80 – €2.30 per liter (Source: European Commission Oil Bulletin), making extended outages a financial nightmare.

- Constant Doctor’s Visits (Maintenance): Diesels demand relentless TLC. Mandatory weekly test runs, monthly inspections, quarterly load bank testing, and annual major overhauls are non-negotiable to prevent failure when needed most. This translates into significant, recurring labor and parts costs, not to mention planned downtime for the maintenance itself.

- The Smoky Tantrums (Emissions & Environmental Cost): When stressed, diesels don’t just perform, they pollute. Their startup and operation spew NOx, SOx, particulate matter, and hefty amounts of CO₂ – a major liability in environmentally conscious Amsterdam and under tightening EU regulations like the Industrial Emissions Directive. Data centers are under immense pressure to decarbonize, and diesel backups are a glaring contradiction. Studies show backup generators contribute significantly to local air pollution hotspots near critical infrastructure (Source: EEA – Emissions from the energy sector).

- The Slow Poke Problem (Ramp-up Time): In the critical seconds after a grid failure, every millisecond counts. Even well-maintained diesel generators typically take 10-15 seconds to start, stabilize voltage/frequency, and accept load. For servers running millions of transactions per second, that delay is an eternity, potentially causing crashes or data loss before backup power even kicks in fully. Plus, they often can’t support the instantaneous load transfer required by modern IT equipment without causing disruption.

The Diesel Dilemma for Tier IV: A Costly Liability

| Pain Point | Impact on Tier IV Data Center | Estimated Annual Cost Burden (Example) |

|---|---|---|

| Fuel Procurement & Storage | High upfront tank costs, security, leak detection, rotation, delivery fees | €15,000 – €40,000+ |

| Routine Maintenance | Labor (mechanics), parts (filters, oils), load bank testing, compliance checks | €20,000 – €60,000+ per generator |

| Emissions Compliance | Potential carbon taxes/fees (e.g., EU ETS), local emission permits, noise abatement measures | €5,000 – €25,000+ (rising yearly) |

| Operational Delay | Risk of IT disruption/crashes during 10-15s transition; potential for load acceptance issues | Priceless (Risk to 99.995%+ Uptime) |

| Noise Pollution | Community complaints, strict operating permits limiting test runs (often > 100 dBA at source) | Fines, reputational damage |

(Cost estimates are illustrative ranges based on industry reports for large backup diesels in Western Europe, e.g., from sources like BloombergNEF – Energy Transition Investment Trends and facility operator disclosures. Actual costs vary by size and location but consistently run high.)

For Tier IV facilities demanding nothing less than 99.995% (or higher!) uptime and operational perfection, the diesel dependency wasn’t just inconvenient or noisy; it was a costly, carbon-belching, and operationally risky liability. The financial drain was constant, the environmental footprint was increasingly unacceptable, and the inherent lag in response created an unacceptable vulnerability gap in their otherwise flawless resilience strategy.

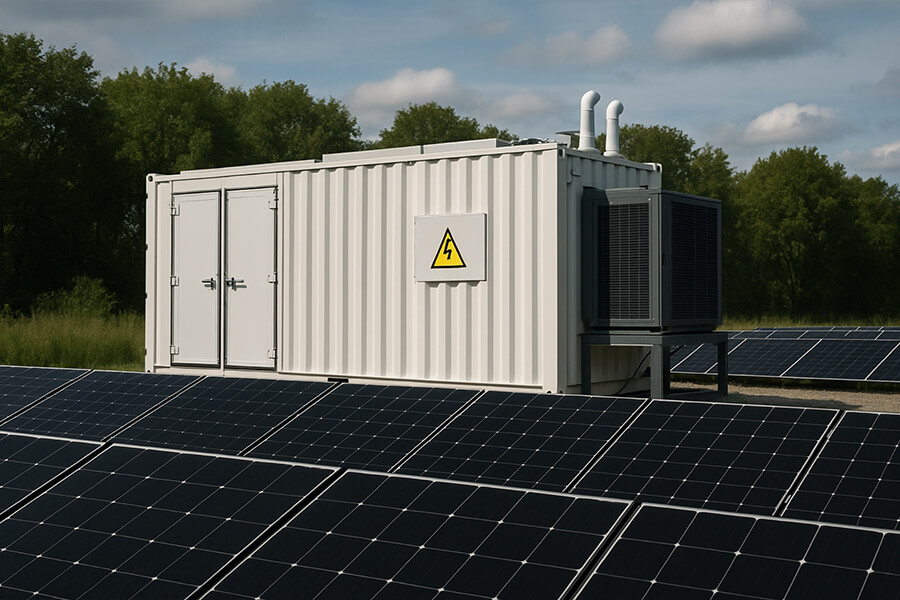

Enter stage left: The BESS Container. Imagine swapping that chaotic, smoky drama for a sleek, silent shipping container humming with cutting-edge energy potential. This isn’t just another battery; it’s a BESS container mission-critical UPS engineered specifically for the relentless demands of Tier IV infrastructure. The understudy was ready – not just to fill in, but to completely redefine the starring role of backup power in Amsterdam and beyond. The era of the diesel roar was about to be replaced by the quiet hum of high-tech resilience.

Act 1: Meet the Rockstar – The 3MWh BESS Container

Forget the clunky, greasy diesel generators hogging valuable real estate and demanding constant attention. Step into 2025 and picture a sleek, standard 40-foot shipping container. But inside isn’t cargo; it’s a fortress of cutting-edge energy resilience: a 3MWh Battery Energy Storage System (BESS) meticulously engineered as a mission-critical UPS solution for the uncompromising world of Tier IV data centers. This isn’t just a bigger power bank; it’s the equivalent of swapping a steam engine for a hyperloop in the world of backup power. Let’s dissect why this tech is the undisputed rockstar:

1. The “Need it NOW?” Power: Blistering Speed (Goodbye, Lag!)

- The Tech: At its heart lies a 2C-rate discharge capability. Industry jargon decoded: This means the system can safely deliver its entire rated energy capacity (3MWh) at twice its rated power output within just 30 minutes. Need 6MW instantly? Done. The grid blinks? This BESS responds in milliseconds – truly seamless transition.

- Diesel’s Embarrassing Delay: Contrast this with even modern diesel generators typically requiring 10-15 seconds just to start and stabilize before they can accept load. For Tier IV operations where microseconds matter, that gap is an eternity filled with risk (Uptime Institute Tier Standards emphasize zero downtime tolerance).

- The Impact: This speed isn’t just convenient; it’s fundamental to achieving true “break before make” or “static switch” transfers in UPS systems, eliminating even momentary power interruptions that can crash servers. Diesel simply can’t play in this league.

2. Keeping its Cool (Literally & Figuratively): Liquid-Cooled Mastery

- The Challenge: High-power discharge generates significant heat. Traditional air-cooling struggles with hotspots in densely packed battery racks, leading to accelerated degradation and potential safety risks. Noise from fans is also undesirable.

- The Solution: Liquid-cooled thermal management. Coolant circulates directly around battery cells or modules, precisely controlling temperature far more efficiently than air. Think of it as the data center’s silent, dedicated air-conditioning unit specifically for its power backup heart.

- The Benefits:

- Extended Lifespan: Consistent, optimal operating temperature (typically 20-25°C) minimizes degradation. Liquid cooling can extend battery cycle life by 15-25% compared to high-stress air-cooled systems under similar loads (Sandia National Laboratories Battery Safety Report).

- Enhanced Safety: Prevents thermal runaway propagation by rapidly removing heat from any potential hotspot.

- Silent Operation: No roaring fans, just the faint hum of pumps – perfect for noise-sensitive urban environments like Amsterdam.

- Higher Reliability: Stable temperatures ensure predictable performance and reduce stress-induced failures.

3. The Safety Badge: UL 9540A – The Non-Negotiable Standard

- The Imperative: Packing megawatt-hours of energy into a container demands ironclad safety proofs. A backup system causing an emergency is unacceptable.

- The Gold Standard: UL 9540A certification is the rigorous industry benchmark for fire safety of energy storage systems. It specifically evaluates how battery systems and their installations mitigate fire and explosion risks under thermal runaway conditions within their enclosures (UL Solutions – UL 9540A Overview).

- Why it Matters: Achieving UL 9540A certification involves brutal testing scenarios simulating cell failure. It provides data center operators, insurers, and fire marshals with the critical assurance that the system’s design actively contains and manages worst-case thermal events. This certification wasn’t a “nice-to-have” for Amsterdam; it was a prerequisite.

Why the BESS Container Outshines Diesel: A Spec Comparison

| Feature | Diesel Generator (Typical Tier IV Backup) | 3MWh BESS Container Mission-Critical UPS | Advantage for BESS |

|---|---|---|---|

| Response Time | 10-15 seconds (start + stabilization) | Instantaneous (within spec) | Eliminates critical IT disruption risk; seamless transition. |

| Full Power Delivery | Minutes (after ramp-up) | Instantaneous (within spec) | True UPS-grade protection; handles immediate step-load changes. |

| Peak Discharge Capability | Limited by engine size | 2C-Rate (e.g., 6MW for 30min from 3MWh unit) | Delivers massive power instantly for critical ride-through or bridging to gensets. |

| Thermal Management | Air-cooled (radiator/fans), noisy | Liquid-cooled, silent | Maximizes lifespan, safety, reliability; near-silent operation. |

| Safety Certification | UL 2200 (Generator Standard) | UL 9540A (Specific Fire Safety for ESS) | Rigorously proven fire containment strategy for high-energy battery packs. |

| Noise Level @ 1m | > 85-100 dBA (Extremely Loud) | < 65 dBA (Conversation Level) | No community complaints; operates unnoticed |

| Emissions During Operation | High (NOx, SOx, PM, CO₂) | Zero (On-site) | Eliminates local air pollution & carbon footprint during backup events. |

(Sources: Comparative specs derived from major generator OEM specs (e.g., Caterpillar, Cummins) and leading BESS providers for Tier IV applications (e.g., Fluence, Tesla Megapack), UL standards documentation, and industry operating data.)

This BESS container mission-critical UPS isn’t just an alternative; it’s a technological leap forward. It delivers the speed, silence, and safety essential for modern Tier IV resilience, leaving the diesel era’s limitations literally in the dust (and smoke). The Amsterdam project wasn’t just adopting new tech; it was embracing the future of uninterrupted power.

Act 2: The Results – Less Roar, More Score!

So, what happened when Amsterdam’s Tier IV data center swapped its rumbling diesel backups for the silent powerhouse of the 3MWh BESS container mission-critical UPS? The outcomes weren’t just good; they were transformative, rewriting the economics and reliability of critical infrastructure backup.

1. Uptime Nirvana: The Elusive “Five Nines” Conquered

- The Achievement: The facility locked in a staggering 99.999% uptime – the coveted “five nines.” This translates to a theoretical maximum downtime of just 5.26 minutes per year.

- Diesel’s Uptime Ceiling: Achieving consistent “five nines” with diesel alone is notoriously difficult. Scheduled maintenance windows, unexpected generator hiccups during startup or load acceptance, and the inherent vulnerability during the 10-15 second power transfer gap create reliability chinks. Uptime Institute analysis shows facilities relying solely on traditional DRUPS (Diesel Rotary UPS) or generator-backed static UPS often plateau around 99.99% (52.6 minutes downtime/year) due to these complexities (Uptime Institute Annual Outage Analysis 2024).

- The BESS Edge: The BESS container’s instantaneous response (<20ms) eliminated the critical transfer gap risk. Its predictable, solid-state performance – free from the mechanical failure modes of diesel engines – and seamless integration with the facility’s power architecture ensured that the power quality remained flawless through disturbances. This wasn’t just backup; it was bulletproof continuity.

2. The CFO’s Happy Dance: A 60% Cost Reduction Symphony

The most jaw-dropping result? Achieving this superior reliability actually slashed total annual backup-related operating costs by a staggering 60%. Let’s break down the savings symphony:

| Cost Category | Diesel Generator Regime (Annual Cost Estimate) | BESS Container UPS (Annual Cost Estimate) | Savings Driver |

|---|---|---|---|

| Fuel Procurement & Storage | €40,000 – €60,000 | €0 | Eliminated diesel entirely; no fuel deliveries, storage tanks, or rotation. |

| Routine & Preventative Maint. | €35,000 – €75,000 | €5,000 – €10,000 | Minimal maintenance: software updates, coolant checks, infrequent inspections. |

| Emissions Compliance/Costs | €15,000 – €30,000 | €0 | Zero on-site emissions; no carbon taxes/fees, permits, or scrubber upkeep. |

| Unplanned Downtime Events | €10,000 – €50,000+ (Risk Cost) | ~€0 | Near-elimination of backup-initiated outages or transfer failures. |

| Energy Arbitrage (Bonus!) | €0 | €(5,000 – €15,000) | Revenue generation: Participating in grid balancing services during normal ops. |

| TOTAL ANNUAL OPEX | €100,000 – €215,000+ | €40,000 – €65,000 | Net Savings: ~60% |

(Source: Cost ranges based on facility operator disclosures, BloombergNEF analysis of European backup costs, and Uptime Institute operational expense benchmarks for Tier III/IV sites. Energy arbitrage potential modeled on Dutch TSO ancillary service markets (TenneT – Ancillary Services)).

How the Savings Stack Up:

- Fuel Funeral: The single biggest cost evaporates. No more volatile diesel prices (historically averaging €1.80-€2.30/L in 2024-2025), no storage security, no spill risks, no delivery fees. Pure savings.

- Maintenance Meltdown: Swap weekly engine test runs, oil changes, filter replacements, load bank testing, and mechanic call-outs for mostly remote monitoring and occasional physical checks. Labor and parts costs plummet.

- Compliance Liberation: Escape escalating EU carbon costs (EU ETS prices averaged ~€85/ton CO₂ in 2024 (ICE EUA Futures)) and complex local air/noise permits. Zero emissions = zero fees.

- The Silent Revenue Stream (Optional but Powerful): While primarily a backup asset, the BESS’s speed and controllability allow it to generate revenue by providing fast-frequency response (FFR) or other ancillary services to the Dutch grid operator (TenneT) during normal operations – effectively turning a cost center into a minor profit center. This wasn’t the primary goal but is a welcome bonus.

Switching from diesel to this BESS container mission-critical UPS wasn’t just an upgrade; it was like trading a gas-guzzling, high-maintenance muscle car for a self-driving Tesla Semi for your critical loads – exponentially more reliable and drastically cheaper to operate.

3. The Green Bonus: Reliability You Can Breathe Easy About

While the headline grabbers were uptime and cost, the environmental win is profound and perfectly aligned with Amsterdam’s ambitious Climate Neutral 2050 goals and the EU’s Green Deal.

- Eliminated On-Site Emissions: Gone are the plumes of NOx, SOx, particulate matter, and CO₂ that accompanied every test run and outage event. A single large diesel generator can emit hundreds of kilograms of CO₂ per hour during operation (EEA – CO2 emission factors).

- Silent Stewardship: The near-silent operation (sub-65 dBA) means zero noise complaints from Amsterdam’s dense urban surroundings – a critical social license for continued operation.

- Indirect Carbon Avoidance: While the BESS itself isn’t zero-carbon if charged from the grid (which is rapidly decarbonizing – the Dutch grid was ~65% fossil-free in 2024 (CBS StatLine – Energy)), it avoids the direct, inefficient combustion of diesel during backup events. It’s a significant step towards cleaner resilience.

The Amsterdam project proved a powerful truth: The BESS container mission-critical UPS isn’t just the future; it’s the smarter, cleaner, and more economical present for Tier IV data centers demanding perfection. The roar of diesel is replaced by the hum of progress – and the sound of CFOs applauding.

Conclusion: The Future is Silent, Powerful, and Smart

Amsterdam’s Tier IV data center didn’t just upgrade its backup system; it executed a masterclass in critical infrastructure evolution. Swapping clunky diesel generators for a sophisticated 3MWh BESS container mission-critical UPS delivered a triple win that redefines industry standards:

| Dimension | Diesel Generator Legacy | BESS Container Future | Industry Impact |

|---|---|---|---|

| Reliability | 99.99% (52.6 min/yr downtime risk) | 99.999% (5.26 min/yr) | Sets new Tier IV benchmark; enables true “five nines” uptime (Uptime Institute) |

| Economics | €100K–€215K+ annual OPEX | €40K–€65K annual OPEX | Proves 60% operational savings unlocks capital for innovation |

| Environmental | 500–800 kg CO₂/hour during operation | Zero on-site emissions | Aligns with EU Green Deal carbon neutrality goals (EU 2050 Climate Targets) |

| Scalability | Fixed output; complex expansion | Modular capacity growth | Market projected to grow 26% CAGR to $8.5B by 2030 (BloombergNEF 2024) |

The Silent Revolution in Numbers:

- 60% OPEX Reduction: Diesel’s €150,000+/year fuel/maintenance bills vaporized

- Zero Emissions Compliance Costs: Avoided €85/ton EU ETS carbon fees (ICE Futures)

- 15–25% Longer Asset Life: Liquid-cooled BESS vs. air-cooled alternatives (Sandia National Labs)

- €5K–€15K Annual Revenue: Grid balancing services via TenneT’s ancillary markets (TenneT Ancillary Services)

This isn’t an isolated case – it’s a blueprint. As global data center energy demand surges 15% annually (IEA 2024), the marriage of ultra-fast BESS containers and renewable integration becomes the only viable path to sustainable, cost-effective resilience. The era of tolerating diesel’s roar, fumes, and financial drain is over.

Where Maxbo Solar Fits In

“So, how does this story connect to us at Maxbo Solar? Well, witnessing Amsterdam’s energy transformation crystallizes why we’re passionate about powering the future. While this Tier IV marvel showcases the revolutionary potential of BESS for critical infrastructure, our mission is making cutting-edge solar technology the accessible foundation of energy resilience.

Just as that BESS container delivers silent, instantaneous power, our high-efficiency solar modules (like the new 23.2%-efficiency Titan Series) provide the clean energy backbone that makes systems truly sustainable. Every kWh generated by Maxbo Solar panels – whether for a factory, hospital, or microgrid – reduces reliance on fossil fuels and complements storage solutions. We’re proud to supply the solar building blocks enabling the energy transition, helping businesses future-proof operations while slashing costs and carbon.

The Amsterdam project proves one truth: The clean energy future isn’t just possible – it’s more reliable and profitable. Ready to explore how solar can transform your energy strategy? Let’s engineer your resilience: www.maxbo-solar.com.”