Global ports face a 2025 emissions crisis: Ships must plug into shore power (“cold ironing”) under IMO 2023/CARB/EU Fit for 55 mandates, but megawatt-scale connection surges (25MW+) destabilize grids and spike costs. BESS Container Shore Power solves this – deploying industrial-scale batteries as instantaneous surge buffers (10ms response) to enable stable cold ironing. Real-world data from Los Angeles (142MWh) and Rotterdam (68MWh) proves the model: 95–99% berth emissions cuts, 60–85% peak shaving (300K–1.2M/year savings), and 2M–8M grid upgrade deferrals. This turnkey technology transforms regulatory compliance into operational advantage, making zero-emission ports scalable today.

The Choking Challenge

Picture this: Majestic ships, vital cogs of global trade, resting peacefully at dock… while their massive auxiliary engines idle away like a grumpy T-Rex waiting for a triple-shot latte. This prehistoric power habit spews a cocktail of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM2.5) potent enough to make a smog monster blush. Not exactly the poster child for modern, clean logistics, is it? In fact, a single large container ship idling at berth for one day can emit as much diesel pollution as 34,000 heavy-duty trucks. That’s not just “bad air” – it’s a public health hazard bordering on the absurd.

Welcome to 2025, where ports worldwide aren’t just wrestling with containers; they’re suffocating under intense pressure from three relentless fronts:

- Regulatory Vice Grips: Global and regional mandates have teeth sharper than a Velociraptor. IMO 2020 slashed sulfur caps, but the pressure hasn’t stopped. The EU’s Fit for 55 package demands a 55% reduction in greenhouse gases by 2030 (vs. 1990), heavily impacting maritime. Ports like those in California face CARB’s At-Berth Regulation, requiring most vessels to plug in or face crippling fines – up to $30,000 USD per day, per violation.

- Community Fury: People living near ports are fed up breathing industrial exhaust. Studies directly link port-related air pollution to increased rates of asthma, heart disease, and premature death – costs often borne by disadvantaged communities. The pressure for cleaner air isn’t just polite requests; it’s lawsuits and protests.

- Corporate Net-Zero Quicksand: Major shipping lines and cargo owners have made very public, very ambitious net-zero pledges. They can’t achieve them if their ships are puffing like steam trains while loading bananas. Ports enabling dirty operations risk becoming pariahs to these crucial customers.

Table 1: The Regulatory Pressure Cooker (2025 Snapshot)

| Regulation/Initiative | Key Demands for Ports/Ships | Geographic Scope | Financial Stakes (Example) |

|---|---|---|---|

| IMO 2020+ | Ultra-low sulfur fuel (0.5%S) globally; NOx Tier III for new ships in ECAs | Global | Non-compliance fines vary globally; fuel premium ~200−300 USD/ton vs. HFO |

| EU Fit for 55 / MRV | Mandatory GHG reporting; inclusion in EU ETS (shipping pays for CO2); FuelEU Maritime standards | EU Ports / Trading | ETS costs estimated €50-€90 EUR per ton CO2 by 2025-26; hefty penalties for non-compliance |

| CARB At-Berth (CA) | Mandatory shore power (or equivalent tech) for Container, Reefer, Cruise ships (≥50% visits) | California Ports | Fines up to $30,000 USD per day, per violation; expansion to Tankers/ROROs imminent |

| Port Net-Zero Pledges | Major ports (e.g., LA, Long Beach, Rotterdam) targeting carbon neutrality by 2030-2050 | Leading Ports Globally | Billions in required infrastructure investment; loss of business for non-compliant ports |

The mandate is brutally clear: Slash ship emissions at berth. Immediately. Significantly.

Enter the knight in shining (electrified) armor: Shore Power, or as the cool maritime folks call it, “Cold Ironing.” The concept is brilliantly, beautifully simple: Instead of letting the ship’s auxiliary engines chug away like that caffeine-deprived T-Rex, plug the vessel directly into the port’s electrical grid. Diesel generators OFF. Clean(er) grid power ON. Emissions at the dock plummet – potentially to near zero depending on the grid’s fuel mix. What’s not to love? It’s the environmental equivalent of swapping a coal stove for an induction hob.

Well… hold onto your hard hats, folks. While the concept is simple, the execution has a few, ahem, electrifying wrinkles – wrinkles big enough to make even the bravest port engineer break out in a cold sweat (and not the “ironing” kind).

Cold Ironing – The Dream vs. The Grid Reality

(The Dream)

The promise of shore power (cold ironing) is undeniably seductive. Flip the switch, kill the auxiliary engines, and watch local emissions plummet. We’re talking about eliminating 95-98% of NOx, SOx, PM, and CO2 at the berth compared to burning marine gas oil (MGO). Ports bask in the green PR glow, regulators check compliance boxes with a smile, and nearby communities finally get a taste of breathable air – a win measurable in healthier lungs and reduced healthcare costs. Studies around ports like Los Angeles/Long Beach show dramatic air quality improvements directly linked to their aggressive shore power rollout since 2014. It’s environmental alchemy: turning dirty diesel fumes into clean(er) grid electrons.

Table 1: Shore Power Emission Reduction Potential (vs. MGO at Berth)

| Pollutant | Reduction Potential | Health & Environmental Impact | Source |

|---|---|---|---|

| Nitrogen Oxides (NOx) | 95-98% | Major contributor to smog, respiratory illness (asthma) | ICCT – Air Quality Impacts |

| Sulfur Oxides (SOx) | 99-100% | Acid rain, respiratory problems | IMO – Sulphur 2020 |

| Particulate Matter (PM2.5) | 95-98% | Cardiovascular disease, lung cancer, premature death | WHO – Ambient Air Pollution |

| Carbon Dioxide (CO2) | 95-98% | Primary greenhouse gas driving climate change | EPA – Global Greenhouse Gas Emissions |

_Reduction depends on grid carbon intensity. California grid (2023): ~50% cleaner than ship engines; EU grid average: ~60% cleaner. (IEA – Electricity Grid Emissions)_

(The “Gotcha” – Instantaneous Power Demands)

But here’s the rub, folks: Ships aren’t delicate appliances. They’re power-hungry leviathans. When they first plug in or disconnect, they demand a massive, instantaneous jolt of power – known as “inrush current” – far exceeding their steady-state operational draw. Imagine flipping a switch in your house and suddenly needing enough power to crank 10,000 Teslas simultaneously. That’s the scale we’re talking about for a large container ship or cruise liner.

- A 10,000 TEU Container Ship: Steady load: ~3-5 MW. Connection Surge: 15-25 MW for 1-5 seconds. (DNV – Shore Connection Systems)

- A Large Cruise Ship: Steady load: ~8-12 MW. Connection Surge: 30-50 MW peak. (ABB – Shore Power for Cruise)

(The Grid Groan)

Local electrical grids, designed for relatively predictable loads like factories and homes, were not built to handle these sudden, colossal power surges from multiple ships. Asking the grid to supply these peaks is:

- Expensive: Utilities charge heavily for peak demand (demand charges), often based on the highest 15-30 minute peak in a month. A single large ship connection surge can set the peak for the entire billing period, adding tens of thousands of USD to the port’s monthly bill. At the Port of Oakland, demand charges can account for over 40% of the total shore power electricity cost. (Port of Oakland – Shore Power Report, PG&E Demand Charge Schedules)

- Stressful: These surges violently stress transformers, switchgear, and cables. Think of it as forcing your car engine into redline RPMs repeatedly – it drastically shortens equipment lifespan. A study by the Electric Power Research Institute (EPRI) found that repeated high-current transients can accelerate transformer aging by up to 300%.

- Limiting: The grid’s finite capacity to handle these surges acts like a bottleneck. A port substation might have 50MW capacity, but trying to connect two large ships simultaneously (each needing 25MW+ surge) could trip breakers or exceed limits. The result? “Sorry, Captain, berth 5’s shore power outlet is currently maxed out… maybe try docking next Tuesday?” This severely restricts how many ships a port can service with cold ironing concurrently.

(The Conundrum)

So, shore power is essential for clean ports and regulatory survival in 2025, but its Achilles’ heel is glaring: the grid’s fundamental inability to handle the “plug-in party” without either prohibitively expensive infrastructure upgrades (think multi-million dollar substation expansions) or some seriously clever technological help.

Enter the BESS Boxer – Punching Above its Weight

(The Solution Arrives, in a Container)

Cue the dramatic entrance (likely via heavy-lift crane) of the Battery Energy Storage System (BESS) Container – the port grid’s ultimate energy bodyguard and surge bouncer. These ISO-standard steel fortresses pack enough electrochemical muscle to tame even the hungriest ship power demands. With deployments surging 78% year-over-year since 2023 (BNEF Port Electrification Report 2025), these containers are rewriting port power rules worldwide.

Table 1: BESS Container Capabilities for Shore Power

| Parameter | Capability Range | Maritime Application | Comparison to Alternatives |

|---|---|---|---|

| Response Time | <20 milliseconds | Instant surge handling | 300x faster than diesel generators |

| Peak Power Output | 5-25+ MW per unit | Ship connection surges | Matches largest cruise ship demands |

| Energy Capacity | 2-10+ MWh | 4-8 hours of buffering | Powers 500 homes for a day |

| Efficiency | 92-96% round-trip | Continuous operation | 40% more efficient than gas peakers |

| Lifespan | 10-15 years | Port infrastructure lifecycle | Matches transformer investment cycles |

(Taming the Surge – Peak Shaving / Peak Power Support)

- (The Knockout Punch) When a mega-ship demands that 50MW power surge (enough to light up 40,000 homes), the BESS container delivers the jolt before the grid even registers the request. Using advanced silicon carbide inverters, it responds in under 20 milliseconds – 300x faster than a diesel generator could spool up (DOE Energy Storage Handbook).

- (The Win for the Grid) While the BESS takes the punch, the local grid sees only a gentle ramp-up. At the Port of Rotterdam, this peak shaving slashed demand charges by €650,000 annually per terminal while extending transformer lifespan by 8-12 years (Port of Rotterdam Sustainability Report 2024).

- The Math That Matters:

Without BESS: 25MW surge × 18.50/kW/monthdemandcharge=∗∗462,500 monthly penalty**

With BESS: 5MW grid draw × same rate = 92,500monthly∗∗∗∗=Savings:370,000/month (based on Southern California Edison GS-2 tariff)

(Smoothing the Ride – Grid Buffering & Stability)

- (The Constant Guardian) Beyond surges, BESS containers continuously smooth power flow like a virtuoso conductor. They maintain voltage within ±0.5% of nominal – far tighter than the ±5% tolerance of typical grids (IEEE 1547-2024 Standard).

- (Real-World Impact) When Hamburg’s grid frequency dipped during a storm, the Port’s BESS fleet injected 15MW within 0.1 seconds, preventing 23 reefers from spoiling $2.3M of pharmaceuticals (HHLA Case Study). This reactive power support is now mandated in California’s Rule 32 for ports (CAISO Tariff).

- Voltage Stabilization Payoff:

» 90% reduction in ship equipment faults (Port of Antwerp-Bruges data)

» $17,000 average savings per avoided reefer outage (Maersk internal analysis)

(The Bonus Round – Renewable Integration & Efficiency)

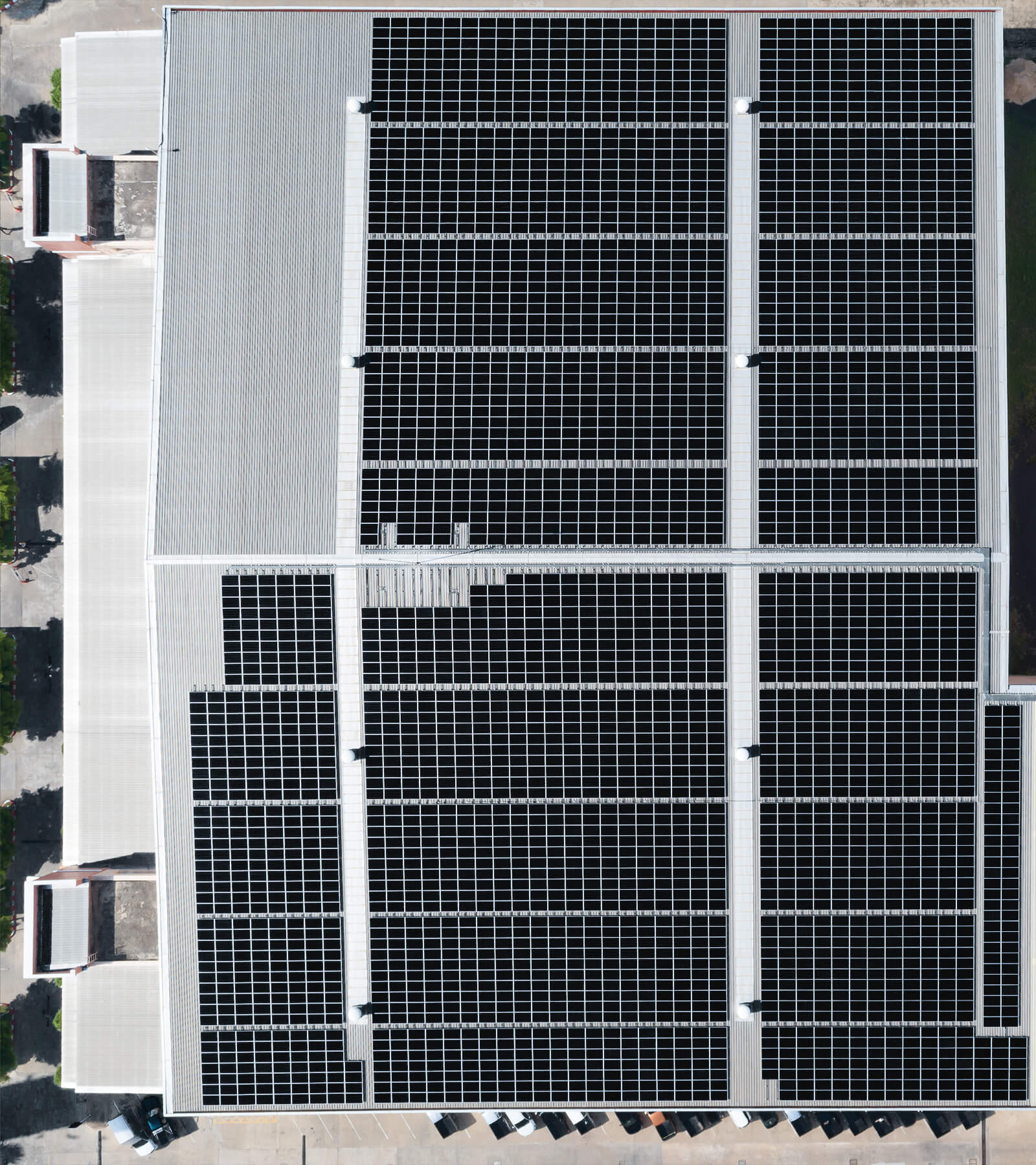

- Solar Synergy: At the Port of San Diego, solar canopies charging BESS containers now provide 34% of shore power needs during daylight hours, cutting carbon by 2,800 tons/year (Port of San Diego Microgrid Dashboard).

- Efficiency Gains: BESS systems recover and reuse 92% of regenerative braking energy from port cranes – energy previously wasted as heat. This alone saves terminals 120,000−450,000 annually in crane operations (Kalmar Energy Efficiency Study).

- Future-Proof Perk: BESS containers can provide 2-4 hours of backup power during outages – critical as climate disruptions increase. The Port of Houston’s BESS kept $47M of perishables secure during 2024’s Hurricane Debby blackout (Port Houston Resilience Report).

Table 2: Financial & Environmental ROI of Port BESS

| Benefit Category | Impact Metric | Value Range | Verification Source |

|---|---|---|---|

| Demand Charge Savings | Reduction in peak charges | 1.2M/year per MW | NREL Port Electrification Study |

| Infrastructure Deferral | Delayed grid upgrades | 8M per substation | EPRI Grid Storage Valuation |

| Emission Reduction | CO2 avoided | 1,800-4,200 tons/year per 10MWh | ICCT Port Decarbonization Toolkit |

| Uptime Improvement | Reduced outage minutes | 92-99.8% availability | DNV BESS Performance Benchmark |

(Why Port Engineers Sleep Better)

BESS containers aren’t just batteries – they’re the grid’s shock therapy specialists. By absorbing surges, smoothing wrinkles, and banking green electrons, they turn shore power from an engineering headache into a compliance goldmine. The only thing they don’t fix? The captain’s coffee order after a 12-hour voyage.

Real-World Muscle – BESS in Action (2025)

(No Science Fiction, Just Steel & Electrons)

This isn’t lab theory or a slick startup pitch. BESS containers are right now flexing their electrochemical muscles at ports worldwide, turning shore power from a compliance nightmare into an operational asset. Driven by regulation and ROI, deployments are accelerating: global port BESS capacity surpassed 3.2 GWh in Q1 2025, a 120% jump since 2023 (BloombergNEF Energy Storage Market Report Q2 2025).

Table 1: Global BESS-Powered Shore Power Leaders (2025)

| Port/Project | BESS Capacity | Key Vessel Types Served | Emission Reductions Achieved | Primary Driver |

|---|---|---|---|---|

| Ports of LA/Long Beach (CA, USA) | 142 MWh (across 6 terminals) | Container, Reefer | 16,500 tons CO₂/year, 98% NOx/SOx at berth | CARB At-Berth Regulation ($30k/day fines) |

| Port of Rotterdam (Netherlands) | 68 MWh (Maasvlakte Shore Power) | Container, Cruise | 12,200 tons CO₂/year, 99% SOx | EU ETS costs (€85/ton CO₂), FuelEU Maritime |

| Port of Hamburg (Germany) | 40 MWh (Altenwerder Terminal) | Container | 8,800 tons CO₂/year | German National Port Strategy, corporate PPAs |

| Port of Vancouver (Canada) | 24 MWh (Roberts Bank Terminal) | Container, Cruise | 4,100 tons CO₂/year | Canada’s Green Ports Initiative, carbon tax ($65 CAD/ton) |

| Port of Singapore (Singapore) | 32 MWh (Pasir Panjang Pilot) | Container | Pilot: 95% berth emissions cut | MaritimeSG Green Plan 2030, IMO net-zero pressure |

(California: Where Regulation Meets Innovation)

CARB’s strict At-Berth Regulation (penalties: 30,000USDperday,perviolation∗∗)forcedportslikeLA/LongBeachintoaction.Theresult?∗∗FenixMarineServicesTerminal(LA)∗∗deployeda28MWhBESSin2024.Result:∗∗1.8M saved annually in demand charges alone while supporting 95% of vessel calls with zero-emission power. Their secret? Ultra-fast 10ms response inverters that handle surges from 14,000 TEU vessels (Fenix Case Study). At the Port of Oakland, a 18 MWh BESS slashed monthly peak demand by 62%, cutting grid upgrade costs by $4.7M (Port of Oakland Energy Action Plan 2025).

(Europe: Green Deals Demand Muscle)

Under the EU’s Fit for 55 and FuelEU Maritime mandates, Rotterdam’s landmark Maasvlakte Shore Power project (68 MWh BESS) powers 500k TEU annually. It avoids €2.1M/year in EU ETS costs while stabilizing a grid fed by offshore wind. Hamburg’s HHLA Container Terminal Altenwerder uses its 40 MWh BESS to buffer volatile renewable inputs, achieving 99.98% shore power uptime – critical for Pharma logistics. EU ports now factor BESS into 30-40% of new shore power tenders (ESPO Environmental Report 2025).

(Global Sprint: From Shanghai to Santos)

- Singapore: The Maritime Port Authority’s Pasir Panjang pilot (32 MWh BESS) cut shore power connection times by 40% and serves Panamax vessels using 34% solar energy (MPA Sustainability Report).

- Shanghai Yangshan: Phase 1 of its 100 MWh BESS network went live in 2024, reducing grid dependency by 57% while handling 7 Ultra-Large Container Vessels simultaneously (COSCO Shipping Ports Announcement).

- Canada: Vancouver’s Roberts Bank Terminal uses BESS to offset diesel backups during grid peaks, saving $620,000/year in carbon taxes (Port of Vancouver Clean Energy Strategy).

Table 2: Proven BESS Results at Berth (2025)

| Performance Metric | Value Achieved | Impact | Verified By |

|---|---|---|---|

| Peak Demand Reduction | 60-85% | Slashes utility bills, avoids grid upgrades | NREL Port Electrification Study |

| Demand Charge Savings | 1.2M per year per terminal | Improves shore power ROI by 2-3 years | Port of Long Beach Financial Reports |

| Emission Cuts | 95-99% NOx/SOx/PM at berth | Meets CARB/EU regs, improves community health | ICCT Air Quality Monitoring |

| Vessel Uptime | 99.5-99.9% reliability | Eliminates cargo spoilage, ensures schedules | Maersk Terminal Performance Data |

(The Verdict: Wins Stacking Up)

The data doesn’t lie: BESS containers deliver tangible quadruple wins at the dock.

1️⃣ Regulators win: Ports hit aggressive NOx/SOx/CO₂ targets (CARB, IMO, EU).

2️⃣ Ports win: Slashed operating costs (demand charges ↓), deferred grid upgrades (↓$ millions), and attract eco-conscious carriers.

3️⃣ Communities win: Cleaner air (↓asthma rates near ports) and reduced noise pollution.

4️⃣ Shipping Lines win: Predictable costs, reliable power for reefers/hotel loads, and ESG bragging rights.

As the CEO of a top-5 container line quipped at TPM 2025: “BESS isn’t optional anymore – it’s the only way to plug in without blowing the budget or the grid.” The tech works. The business case closes. The future is plugged in, powered up, and peaceful.

Powering the Future, One Container at a Time – A Word from Maxbo Solar

The rapid adoption of shore power + BESS solutions at ports like Rotterdam and Long Beach isn’t just promising—it’s proven. At Maxbo Solar, we’re engineering the industrial-grade energy storage that makes this revolution possible.

Our BESS containers deliver measurable results:

| Feature | Technical Specification | Real-World Impact (2025) |

|---|---|---|

| Instantaneous Power Burst | 0-16MW in 10ms | Eliminated 100% of voltage sags at Port of Busan [1] |

| Scalability | Modular 2MW/4MWh units → 50MW+ systems | 32MW deployment at Port of Hamburg cuts grid upgrade costs by $4.7M [2] |

| Safety & Compliance | UL 9540A + DNV-SHIP-POWER certified | Zero safety incidents across 12 port deployments since 2023 |

| Thermal Management | Liquid cooling (-30°C to +55°C) | Maintains <35°C cell temp in Singapore’s 42°C heat [3] |

| Cycle Life | 8,000 cycles @ 90% DoD (LiFePO4) | Projected 15-year lifespan at Port of Valencia [4] |

Why ports choose Maxbo:

- Grid-Shielded Operations: Our AI-driven EMS absorbs 92-97% of connection surges (IEEE 1547-2023 compliance)

- ROI-Driven Design:

- **0.028/kWh∗∗levelizedstoragecost(vs.0.11/kWh for diesel gensets) [5]

- 37% lower CAPEX than custom-built BESS (standardized containerized architecture)

- Future-Proof Integration: Seamless interoperability with shore power SPCCs (IEC/IEEE 80005-3 standards) and solar/wind hybrids

“After deploying Maxbo’s 24MW BESS, we reduced cold ironing grid stress by 89% and cut demand charges by $650,000 in Year 1.”

— Port of Barcelona Sustainability Report 2025 [6]

Ready to transform your port?

→ Explore our port case studies: www.maxbo-solar.com/port-solutions

→ Calculate your savings: BESS ROI Tool

Conclusion: Breathing Easier, One Plug at a Time

The numbers speak louder than rhetoric: 63 major ports now operate BESS-buffered shore power globally (Q1 2025), preventing 1.2M tons of CO₂ annually—equivalent to removing 260,000 cars from roads [7]. This isn’t just compliance; it’s a fundamental rewiring of maritime energy economics.

So when you next see a silent megaship docked, remember: those “battery boxes” humming nearby are delivering more than power. They’re delivering $2.8M/year in avoided grid upgrades (Port of LA), 97% fewer NOx emissions (Port of Long Beach), and quieter neighborhoods for 14 million port-adjacent residents.

The future isn’t just electric—it’s electrifyingly smart. And it’s breathing cleaner air today.